Stone Process Water

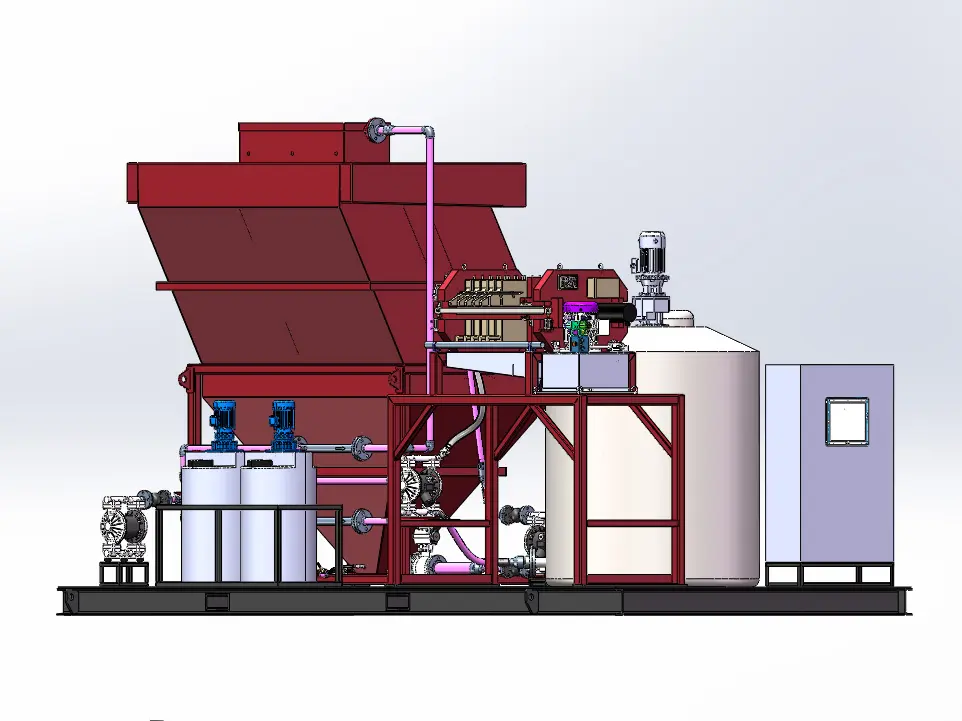

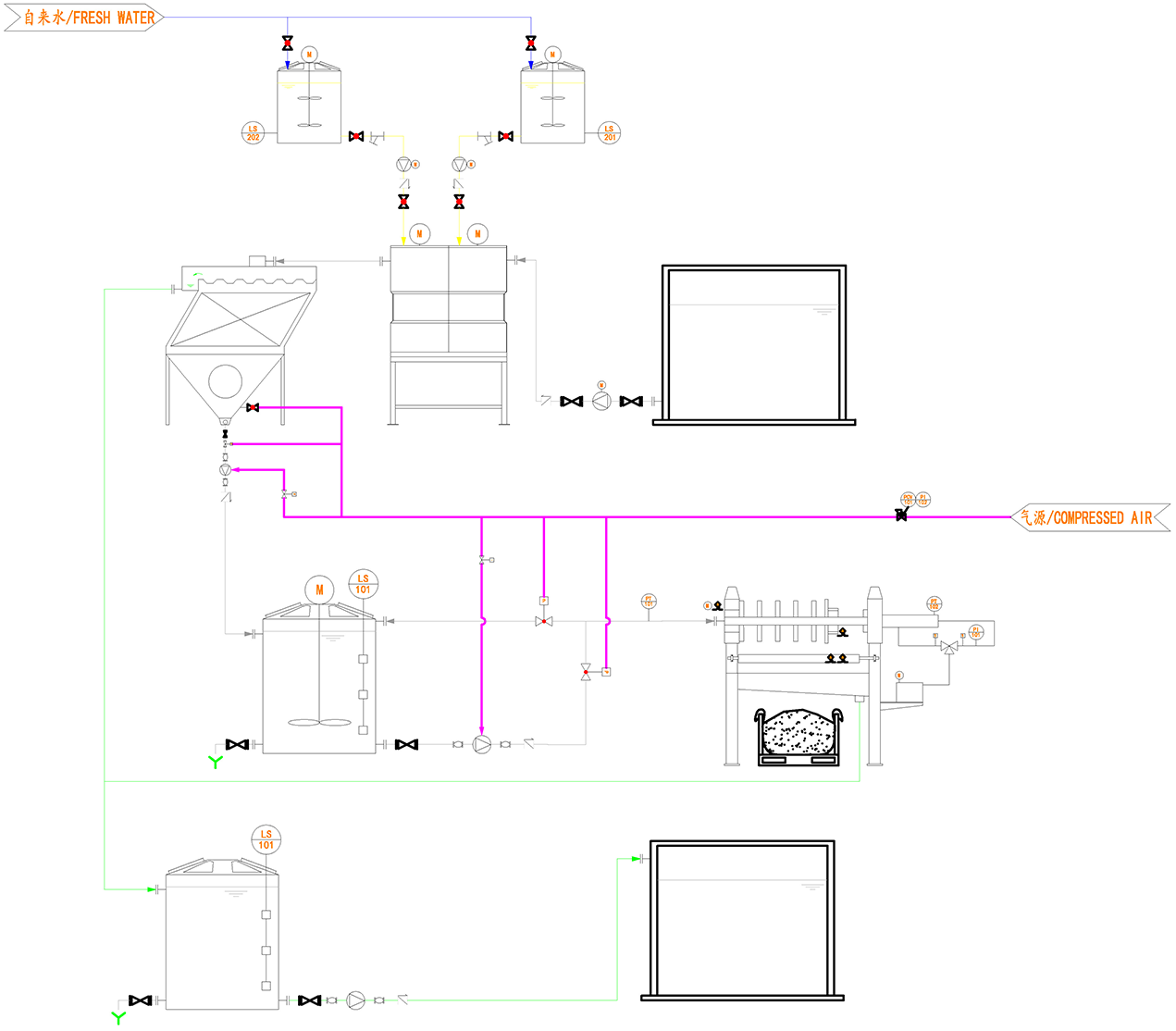

Process flow diagram

Equipment list

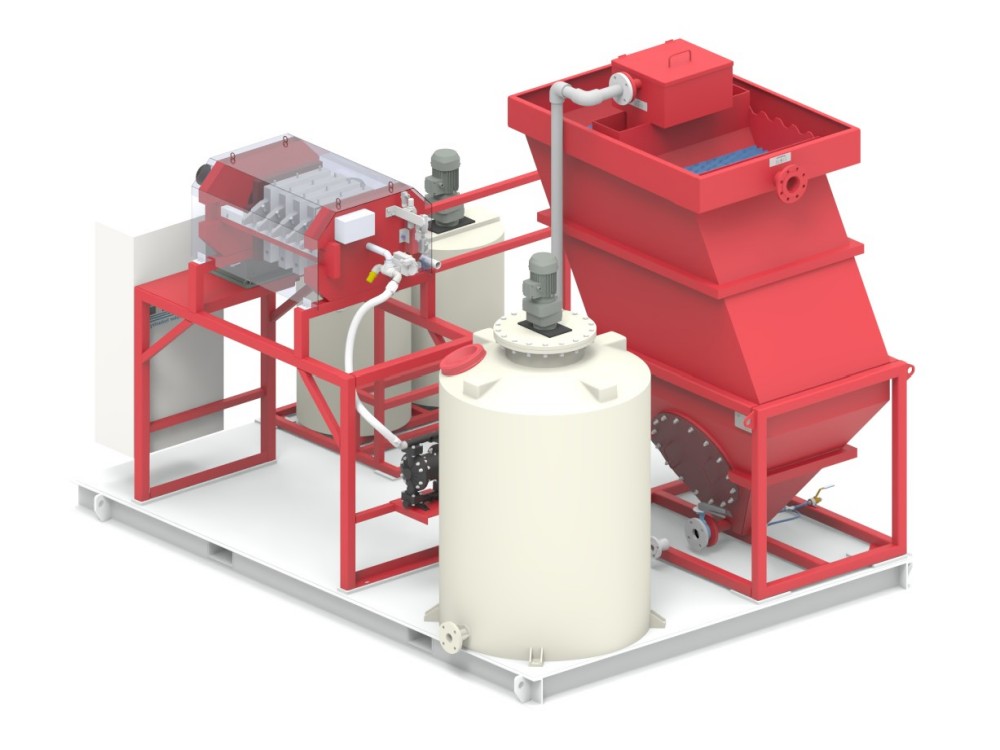

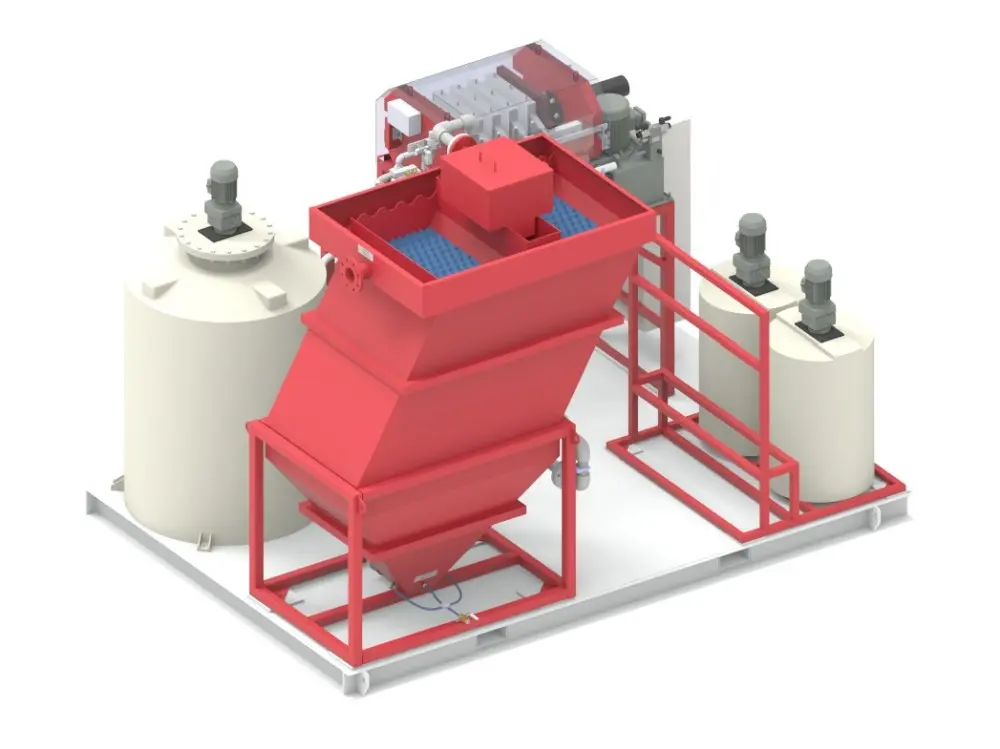

Capacity 5-75m³/h

Name |

Basic system |

Quantity |

Senior system |

Quantity |

Full system |

Quantity |

System description |

Reaction system |

Feeding pump |

1 unit |

Feeding pump |

1 unit |

Feeding pump |

2 units |

The reaction system mainly doses right chemicals such as coagulants and coagulants to the sludge to induce flocculation of the sludge particles and improve their dewatering properties. |

Pipeline mixers |

2 pieces |

MR reaction cell |

1 set |

MR reaction cell |

1 set |

||

PAM dosing drum |

1 piece |

PAM dosing drum |

2 pieces |

PAM integrated dosing device |

1 set |

||

PAM dosing pump |

1 unit |

PAM dosing pump |

1 unit |

PAM dosing pump |

2 units |

||

PAC dosing drum |

1 piece |

PAC dosing drum |

2 pieces |

PAC dosing drum |

2 pieces |

||

PAC dosing pump |

1 unit |

PAC dosing pump |

1 unit |

PAC dosing pump |

2 units |

||

Flowmeter |

/ |

Flowmeter |

/ |

Flowmeter |

1 piece |

||

Sedimentation system |

VMC |

1 unit |

VMC |

1 unit |

VMC |

1 unit |

The sedimentation system is mainly for thickening the effluent and facilitating filter presses. |

Pneumatic Drainage Valve |

1 piece |

Pneumatic Drainage Valve |

1 piece |

Pneumatic Drainage Valve |

1 piece |

||

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

||

Water reuse systems |

Water collection tanks |

1 piece |

Water collection tanks |

1 piece |

Water collection tanks |

1 piece |

The water collection system is mainly to reuse the supernatant after concentration to reduce cost and save money. |

Drainage pump |

1 unit |

Drainage pump |

1 unit |

Drainage pump |

2 units |

||

Filtration system |

Mixing tanks |

1 piece |

Mixing tanks |

1 piece |

Mixing tanks |

1 piece |

The main function of the filter press system is solid-liquid separation |

Feeding pump |

1 unit |

Feeding pump |

1 unit |

Feeding pump |

2 units |

||

KMP |

1 set |

KMP |

1 set |

KMP |

1 set |

||

Control system |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

The automation of all our equipment will be integrated into this system and will be fully automated. |

Accessaries |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Cables and pipe and valve fittings required within the system, depending on the customer's site. |

Please request a detailed list of system from our sales consultant.

Function comparison

Function |

Basic system |

Senior system |

Full system |

Fully automated control |

√ |

√ |

√ |

Faulty alarm |

√ |

√ |

√ |

Automatic reaction vessels |

- |

√ |

√ |

Automatic standby switchover |

- |

- |

√ |

Automatic dosage adjustment |

- |

- |

√ |

Inverter control or not |

- |

- |

√ |

Time between infusions |

4 hours |

8 hours |

Fully automatic |

Optional features

Serial number |

Name |

Specifications |

Function |

1 |

Special anti-corrosion |

FRP Coating for the liquid connection parts |

Prevents corrosion from high acids, salts, fluorine, etc. |

2 |

Special materials |

304/316L etc. |

According to the user's material characteristics |

3 |

Skid mounted |

Patterned steel platform + fixed bracket + wire channel, piping, cables, etc. |

Easy to install, transport and flexible to move |

4 |

PH automatic adjustment |

PH online monitoring + integrated control + acid and alkali dosing system |

Enables the effluent water to reach the standard PH value. |

5 |

Precision filters |

Containing multi-stage centrifugal pumps |

Reducing the suspended solids content of filtrate and regulating water quality |

6 |

Flameproof |

DIIBT4/CT4 etc. |

Electrical components, motors, etc. placed in explosion-proof areas are classified according to different levels. |

7 |

Conveyor systems/staging systems |

Conveyor / Hopper |

Mud cake can be collected by conveying equipment or staging systems, reducing labour. |

Product Introduction

Stone processing wastewater is characterized by a complex and multifaceted composition that presents significant environmental and operational challenges. At the forefront of its defining traits is the remarkably high concentration of suspended solids (SS), predominantly consisting of fine stone powder and dust particles. Generated during various stages of stone processing, including quarrying, cutting, shaping, and polishing, these minute particles can reach levels several times higher than those permitted in typical industrial effluents. In large - scale stone processing facilities, the SS concentration can surge to thousands of milligrams per liter, turning the wastewater into a turbid, muddy - looking liquid. The presence of such a high SS load not only impairs the aesthetic quality of the discharged water but also clogs drainage systems, sedimentation tanks, and filtration equipment, leading to increased maintenance costs and reduced operational efficiency.

The alkaline pH of stone processing wastewater, typically ranging from 8 to 12, is another critical characteristic deeply rooted in its sources. Chemical additives play a substantial role in elevating the alkalinity. For instance, in the stone cutting process, water - based cutting fluids containing alkaline substances are often used to cool the cutting tools and lubricate the contact surfaces, preventing overheating and excessive wear. These additives dissolve in the water, increasing its hydroxide ion concentration and raising the pH. Additionally, the natural composition of many stones contributes to the alkalinity. Limestone, marble, and dolomite, for example, contain carbonate minerals that react with water and atmospheric carbon dioxide, producing bicarbonate and carbonate ions, which further contribute to the alkaline environment. An alkaline pH can cause corrosion of metal pipes and equipment if not properly managed and can disrupt the natural pH balance of receiving water bodies, harming aquatic organisms sensitive to pH fluctuations.

The potential presence of heavy metals such as lead (Pb), chromium (Cr), and nickel (Ni) in stone processing wastewater adds another layer of complexity and concern. These heavy metals can be inherent in the stone itself, leaching out during processing as the stone is fragmented and exposed to water. Some stones, especially those sourced from geological formations with elevated metal concentrations, may contain trace amounts of heavy metals within their mineral structures. Moreover, heavy metals can also enter the wastewater from the processing equipment and machinery. For example, certain types of cutting tools and abrasives may contain metal components that gradually wear off and dissolve in the process water over time. Even at low concentrations, heavy metals are highly toxic and persistent in the environment. They can accumulate in soil, plants, and aquatic life, entering the food chain and posing severe health risks to humans and wildlife, including neurological disorders, organ damage, and cancer.

Organic pollutants from processing agents are yet another significant component of stone processing wastewater. Oils and coolants used in the machining of stones, such as mineral - based cutting oils and synthetic lubricants, contribute to the elevated chemical oxygen demand (COD) and biological oxygen demand (BOD) levels. These organic substances require oxygen for decomposition in water bodies. When large amounts of stone processing wastewater with high COD/BOD are discharged into rivers, lakes, or streams, the oxygen - consuming decomposition processes can deplete the dissolved oxygen in the water, creating hypoxic or anoxic conditions. Such oxygen - starved environments are lethal to fish and other aerobic aquatic organisms, leading to mass die - offs and disrupting the entire aquatic ecosystem.

The high hardness of stone processing wastewater, caused by the dissolution of calcium and magnesium ions, is a result of the interaction between water and stone minerals. As water comes into contact with calcium - and magnesium - rich stones during the processing operations, these ions are released into the water, forming calcium and magnesium salts. High - hardness water can cause scale formation on the inner surfaces of pipes, heat exchangers, and other equipment. Over time, these scale deposits reduce the flow capacity of pipes, decrease the efficiency of heat transfer in equipment, and may even lead to equipment failure. In water treatment processes, high hardness also complicates the purification procedures, as additional steps are often required to remove or reduce the calcium and magnesium ions to prevent scale - related issues.

The presence of oil and grease residues in stone processing wastewater further exacerbates its negative impacts. These residues, which can come from lubricating oils used in machinery, release agents applied during stone shaping, and protective coatings, form a persistent layer on the water surface. This oily film not only obstructs the exchange of gases between the water and the atmosphere but also adheres to the surfaces of soil particles when the wastewater infiltrates the ground. The oil - contaminated soil can lose its porosity and permeability, impeding water infiltration and root growth of plants. In aquatic environments, the oil and grease residues can coat the feathers of waterfowl and the gills of fish, causing physical harm and interfering with their natural functions. If left untreated, stone processing wastewater with its complex mixture of pollutants can trigger a cascade of environmental problems, from water turbidity and soil contamination to long - term ecosystem toxicity, making proper treatment and management essential to mitigate its detrimental effects.