Solar products wastewater

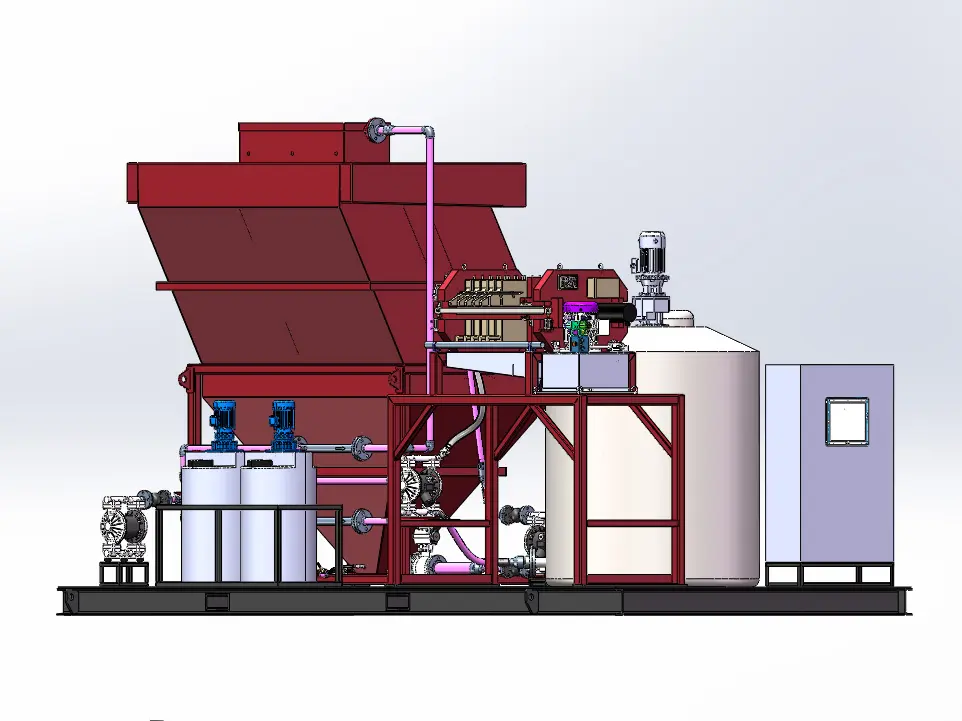

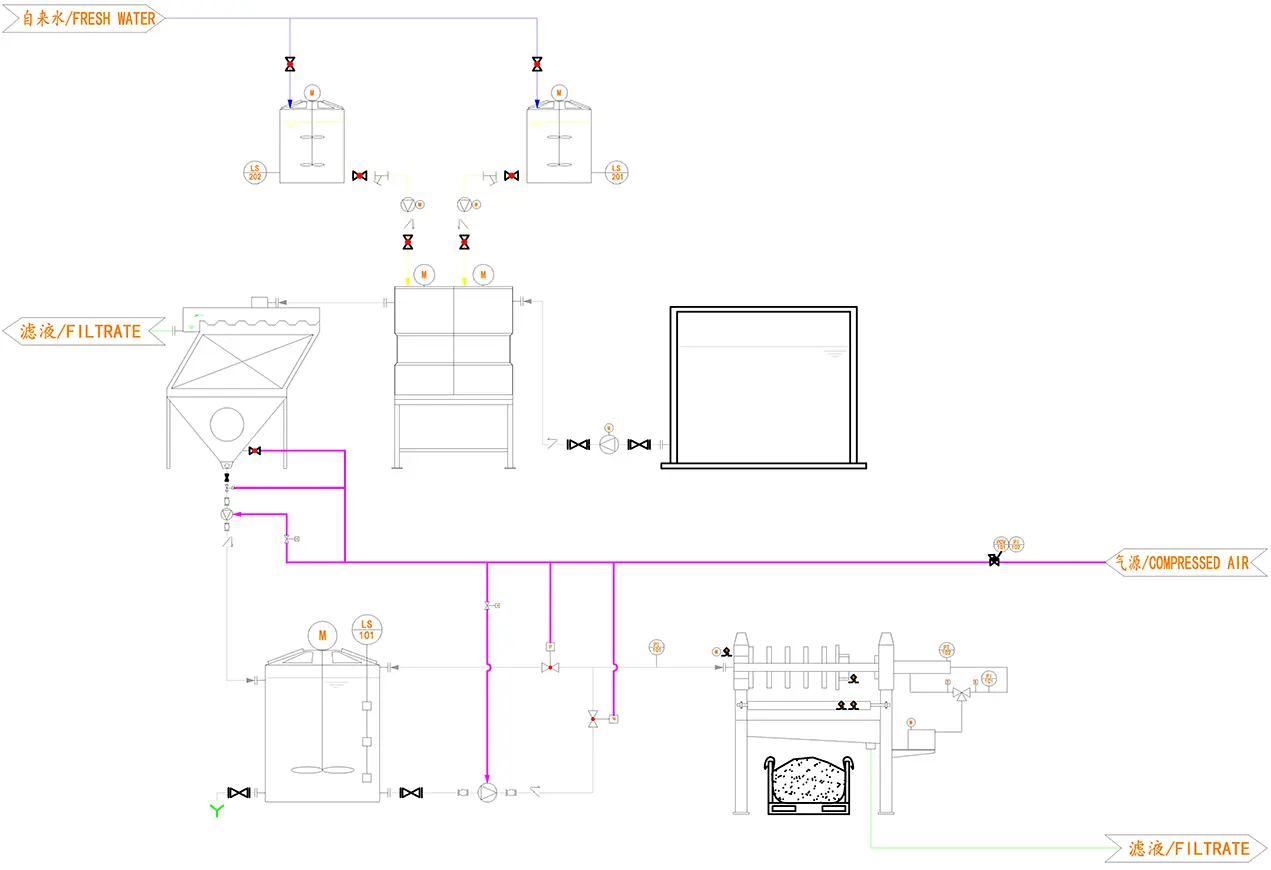

Process flow diagram

Equipment list

Capacity 5-75m ³/h

Name |

Basic system |

Quantity |

Senior system |

Quantity |

Complete system |

Quantity |

System description |

Reaction system |

Sludge pump |

1 unit |

Sludge pump |

1 unit |

Sludge pump |

2 units |

The reaction system mainly doses right chemicals such as coagulants and coagulants to the sludge to promote the flocculation of sludge particles and improve its dehydration performance. |

Pipeline mixer |

2 pieces |

MR reaction tank |

1 set |

MR reaction tank |

1 set |

||

PAM dosing bucket |

1 piece |

PAM dosing bucket |

2 pieces |

PAM integrated dosing device |

1 set |

||

PAM dosing pump |

1 unit |

PAM dosing pump |

1 unit |

PAM dosing pump |

2 units |

||

PAC dosing bucket |

1 piece |

PAC dosing bucket |

2 pieces |

PAC dosing bucket |

2 pieces |

||

PAC dosing pump |

1 unit |

PAC dosing pump |

1 unit |

PAC dosing pump |

2 units |

||

Flowmeter |

/ |

Flowmeter |

/ |

Flowmeter |

1 piece |

||

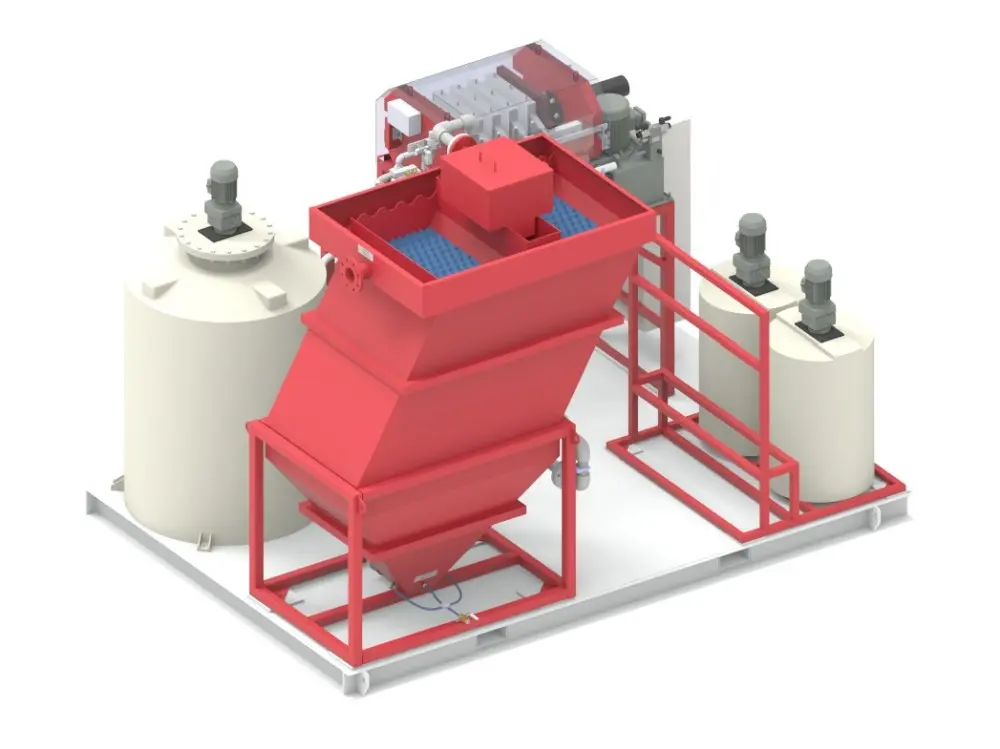

Sedimentation system |

VMC |

1 unit |

VMC |

1 unit |

VMC |

1 unit |

The sedimentation system is mainly used for concentration treatment of sewage, facilitating pressure filtration. |

Pneumatic sludge discharge valve |

1 piece |

Pneumatic sludge discharge valve |

1 piece |

Pneumatic sludge discharge valve |

1 piece |

||

Sludge pump |

1 unit |

Sludge pump |

1 unit |

Sludge pump |

2 units |

||

Drainage pump |

1 unit |

Drainage pump |

1 unit |

Drainage pump |

2 units |

||

Pressure filtration system |

Mixing tank |

1 piece |

Mixing tank |

1 piece |

Mixing tank |

1 piece |

The main function of the pressure filtration system is solid-liquid separation |

Feeding pump |

1 unit |

Feeding pump |

1 unit |

Feeding pump |

2 units |

||

KMP |

1 set |

KMP |

1 set |

KMP |

1 set |

||

Control system |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

All automation control of equipment provided by our company will be integrated into this system and run fully automatically |

Accessaries |

Pipelines, valves, cables, etc |

1 batch |

Pipelines, valves, cables, etc |

1 batch |

Pipelines, valves, cables, etc |

1 batch |

The specific quantity of cables and pipe valves required within the system depends on the customer's on-site situation. |

Please request a detailed list of system from our sales consultant.

Function comparison

Function |

Basic system |

Senior system |

Complete system |

Fully automated control |

√ |

√ |

√ |

Fault alarm |

√ |

√ |

√ |

Automatic reaction container |

- |

√ |

√ |

Automatic backup switching |

- |

- |

√ |

Automatic regulation of dosing |

- |

- |

√ |

Frequency conversion control or not |

- |

- |

√ |

Soaking interval time |

4 hours |

8 hours |

Fully automatic |

Optional features

Serial number |

Name |

Specifications |

Function |

1 |

Water Reuse |

PE tank+pump+liquid level gauge+integrated control |

Transport the supernatant to the production line for reuse using pressurized transportation method |

2 |

Special anti-corrosion |

FRP Coating for the liquid connection parts |

Prevent corrosion caused by high acid, high salt, high fluoride, etc |

3 |

Special materials |

304/316L, etc |

Selection based on user material characteristics |

4 |

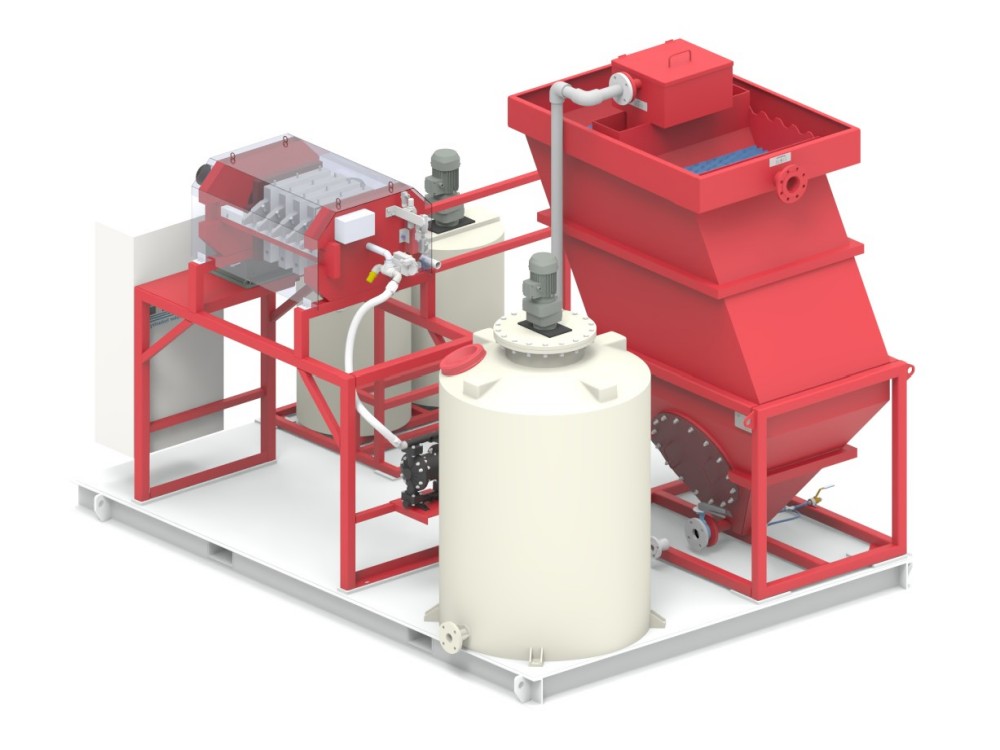

Overall Skid Installation |

Patterned steel platform+fixed bracket+trunking, pipelines, cables, etc |

Easy to install, transport, and move flexibly |

5 |

PH automatic adjustment |

PH online monitoring+integrated control+acid-base dosing system |

Enable the effluent to meet the standard pH value |

6 |

Precision filter |

Including multi-stage centrifugal pump |

Reduce the content of suspended solids in the filtrate and regulate water quality |

7 |

Explosion-proof |

DIIBT4/CT4, etc |

Electrical components, motors, etc. placed in explosion-proof areas are classified according to different levels |

8 |

Conveying system/temporary storage system |

Conveyor/sludge storage hopper |

Mud cakes can be collected through conveying equipment or temporary storage systems, reducing manual labor. |