Kitchen Waste Disposal

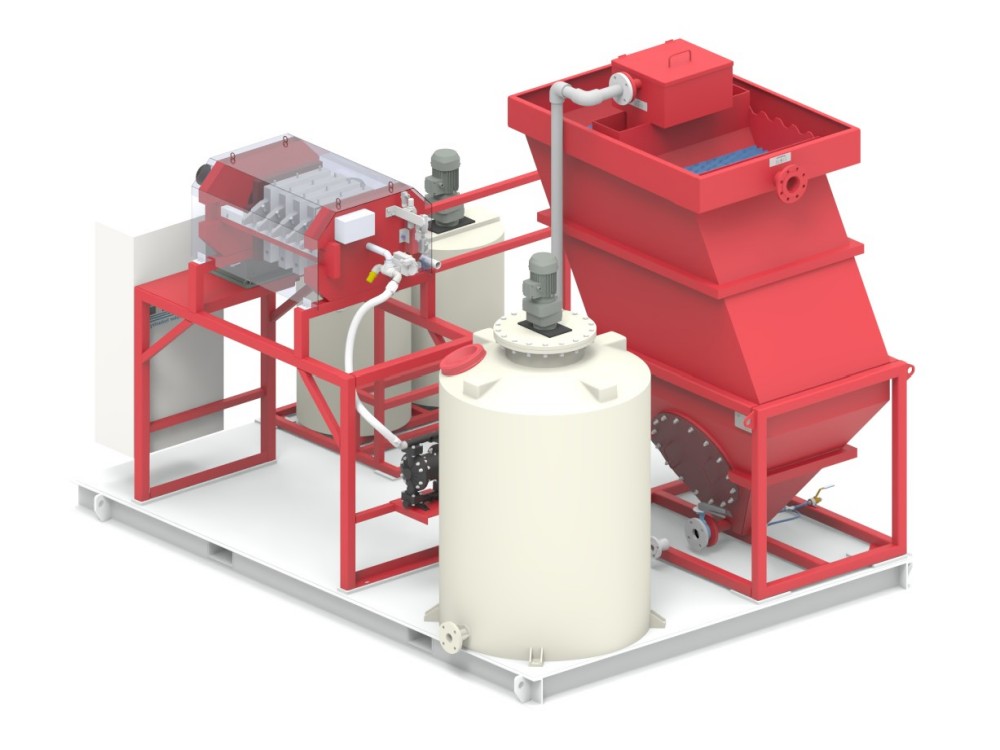

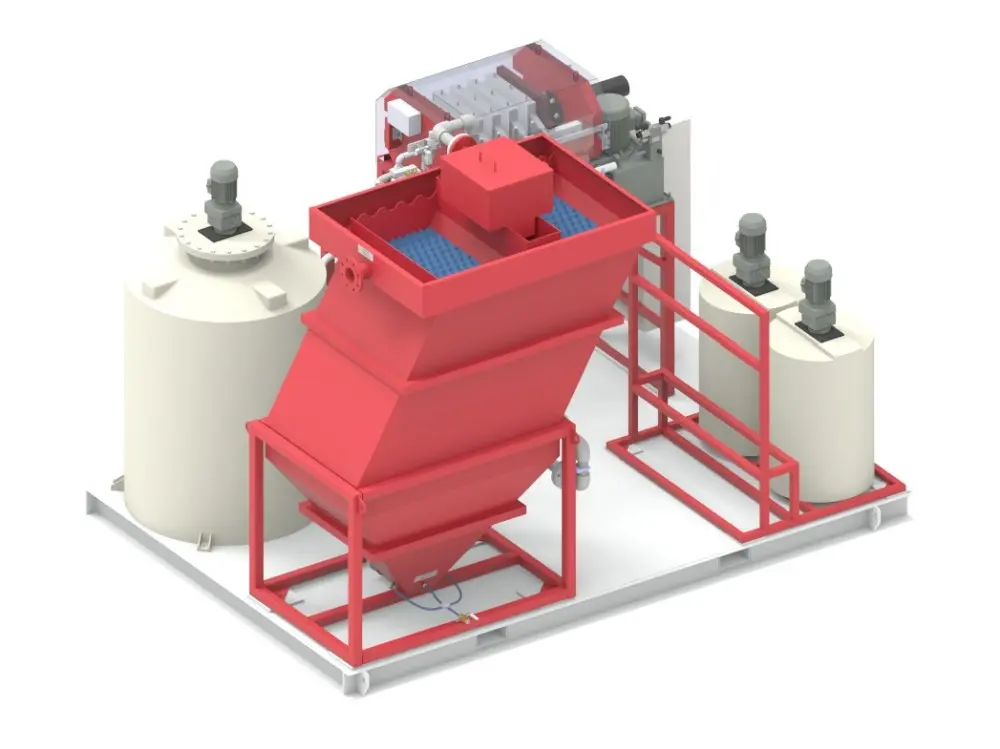

Performance characteristics

1.The whole 304 stainless steel countertop ensures the maximum hygiene and cleanliness;

2.Pneumatic vacuum diaphragm valve is adopted, and the service life is not less than 500,000 times of opening and closing.

3.Equipped with a crushing and grinding system and a centrifugal dewatering device. The crushing and grinding system is made of stainless steel 9CR18, which has a long service life; the centrifugal dewatering technology removes more water and has high dewatering efficiency.

4.Equipped with anti-foreign body locking function, metal foreign bodies can be easily removed when entering the knife disk;

5.Equipped with a handheld high-pressure water gun, convenient for equipment shell cleaning;

6.The discharge port is equipped with an independent control device, which is linked with the vacuum pump host;

7.The optional big data intelligent cloud platform monitoring system is equipped with remote control, automatic fault repair, real-time monitoring of equipment operation and other functions. It is equipped with overvoltage, overcurrent, phase loss, short circuit, overheating and other fault alarm and automatic protection functions.

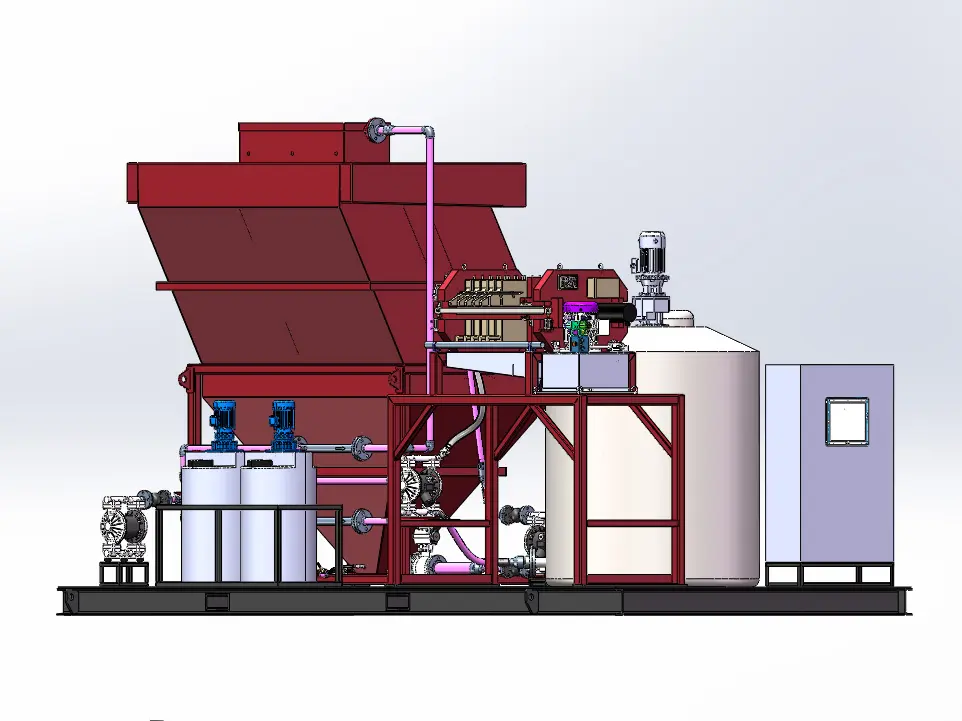

Processing capacity and parameters

Unit type |

KQ-KG-TFK-300 |

KQ-KG-TFK-450 |

Equipment size |

1100*760*900/150 |

1100*760*900 |

Main material |

5mm thick 304# stainless steel |

5mm thick 304# stainless steel |

handling capacity |

300KG/H |

450KG/H |

characteristic |

One-way job design |

Bidirectional job design |

power |

AC380V,3PH+N+PE,3KW |

AC380V,3PH+N+PE,3KW |

Water pressure |

2-4bar |

2-4bar |

Water inlet |

DN15 |

DN15 |

Feed pipe diameter |

DN65 |

DN65 |

reference price |

120000 |

130000 |

Installation requirements

1. Power supply: 380V/4 square 5 cable with independent air switch;

2. Water supply: DN15 cold water (0.4—0.6MPa);

3. Connection to vacuum pipe: DN65

4. The connecting pipe between the discharge port and the storage tank shall be DN65PVC pipe or stainless steel pipe;

5. Connect the power supply according to the standard.

Applicable scenarios

Hotels, commercial complexes, restaurants, and food processing plants being prime examples.

In hotels, these scenarios span multiple functional areas. The high-volume cooking and food assembly operations here require efficient handling of waste management systems if applicable as they deal with stains, dirt, and require significant amounts of water and cleaning agents, mirroring the processing requirements of other industrial - scale operations.

Commercial complexes are vast, multifaceted entities. They house a multitude of retail stores, offices, and entertainment venues, all of which generate waste and require maintenance, as maintaining high - quality hygiene standards is essential for customer satisfaction and the overall reputation of the complex.

Restaurants, whether fine - dining establishments or casual eateries, are central to the food service industry. The constant use of knives, cutting boards, and cooking utensils leads to the generation of food debris and requires regular cleaning and sanitization. Dishwashing rooms are equally important, where stacks of plates, glasses, and cutlery need to be thoroughly cleaned after each service. The water used in dishwashing often contains grease, food particles, and detergents, and proper treatment or management of this wastewater is vital. Garbage rooms in restaurants store food waste before disposal, and effective waste compaction methods are necessary to ensure a clean and healthy environment for both staff and customers.

Food processing plants are large - scale industrial facilities with highly specialized operations. From washing and peeling fruits and vegetables to processing meat and dairy products, each step involves significant amounts of water usage, waste generation, and the need for strict hygiene control. For example, in meat processing plants, the deboning and cutting processes produce blood, fat, and bone fragments that must be managed properly. Advanced waste management systems are required to comply with environmental regulations and prevent contamination.

In essence, these applicable scenarios cover diverse environments, all of which share common challenges related to waste management, hygiene maintenance, and efficient processing, making them suitable candidates for our product and solutions.