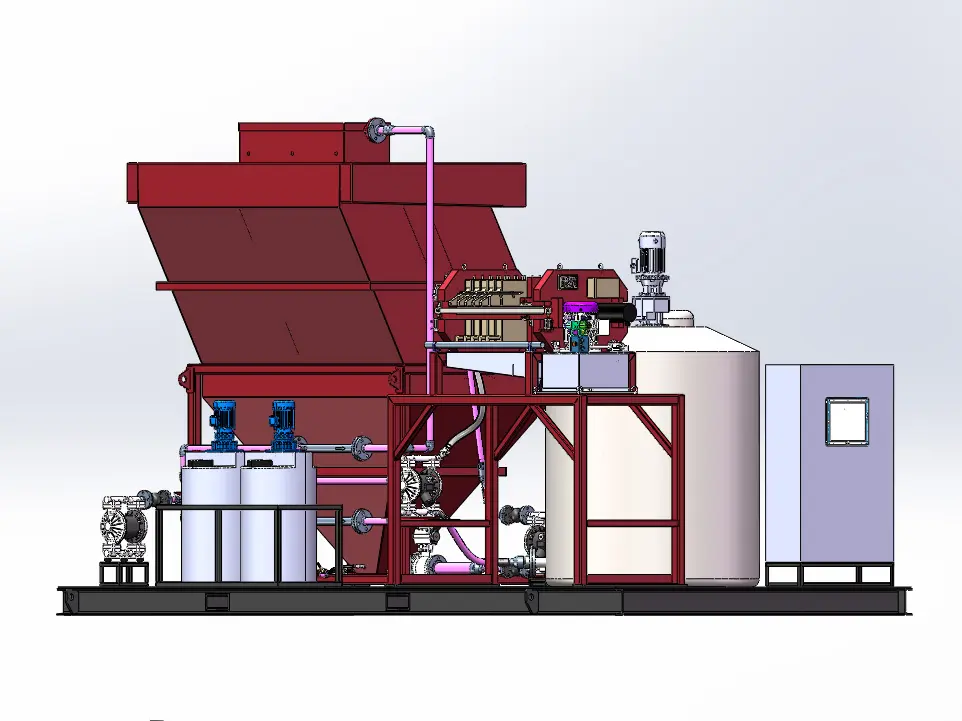

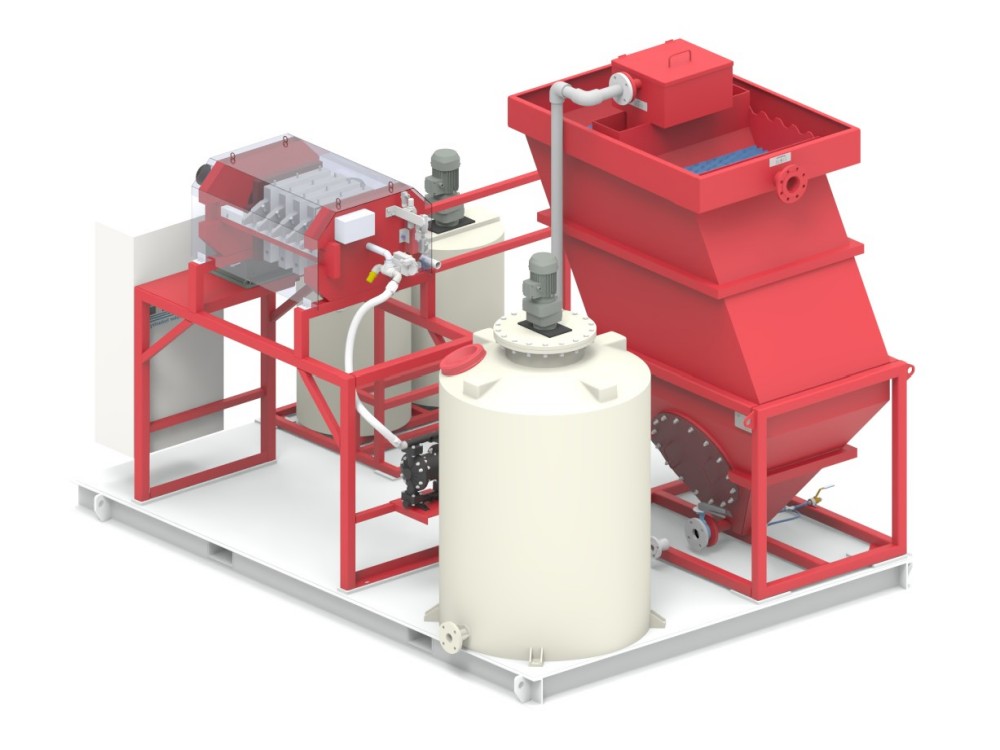

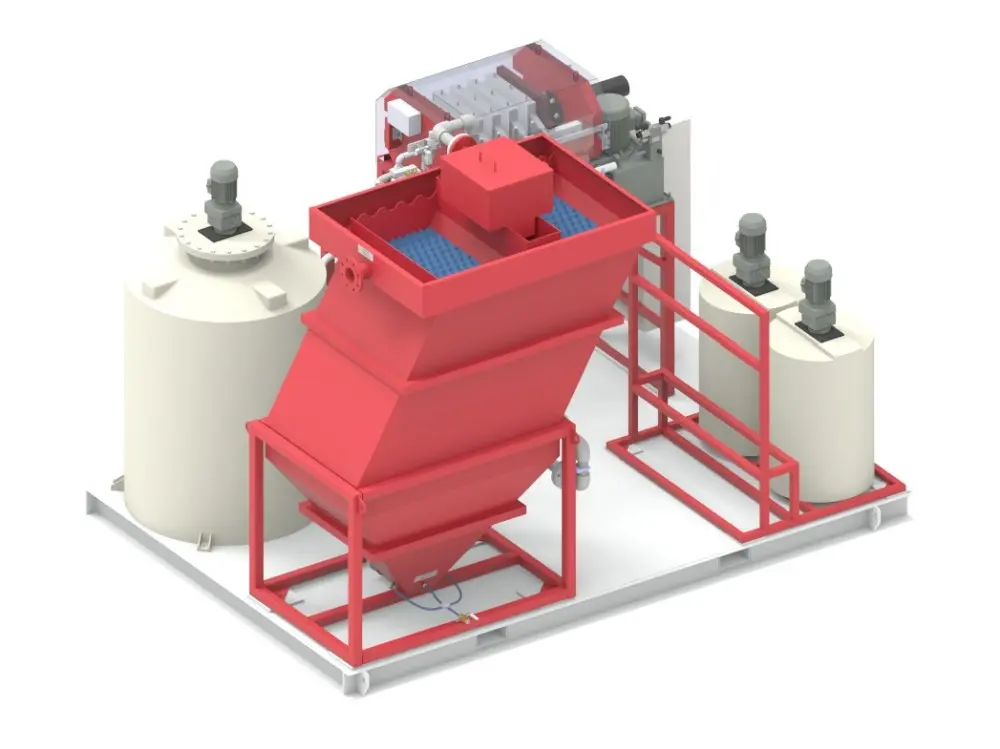

Kitchen Waste Dewatering Press

equipment characteristics

1. Low operating cost

The screw press adopts the principle of physical squeezing and dewatering. No additional heat source is required in the process of dewatering, and it consumes very little energy compared with similar drying equipment.

2. Continuous operation with large processing capacity

The parameters of the spiral helix are analyzed by mechanical calculation, and special processes are used to increase the axial thrust, so as to completely solve the problems caused by slipping, bridge, return material, shaft reporting and other reasons that cannot work continuously, and greatly increase the processing capacity per unit time.

3 .The moisture content of the slag is low

According to the data of moisture content, molecular water ratio, viscosity, fiber content, water absorption, toughness, organic or inorganic substances of different materials, calculate the parameters suitable for the material, and make full use of physical pressing to reduce the moisture content of extruded material.

4. Wear and corrosion resistant

The key parts of the screw press are sprayed with wear-resistant layer, and the surface of the screw screw blade is welded with a layer of alloy blade to increase wear resistance; the core parts are made of 304 stainless steel, which is acid resistant, alkali resistant and corrosion resistant, thus greatly extending the service life of the equipment.

5. No additional agents are required

The sieve with 0.3MM-1.0MM gap can be selected according to the properties of the material to be dehydrated. No flocculant or other agents need to be added in the dehydration process, so no additional cost is required, and no chemical components will affect the secondary utilization of the material.

equipment model and parameters

Model |

Power (KW) |

Outline dimension (mm) |

Processing capacity (m³/h) |

Filter diameter (mm) |

Reference price (YUAN/unit) |

KQ-KG-LY-200 |

7.5 |

2500*765*1395 |

3 |

200 |

thirty-five thousand |

KQ-KG-LY-300 |

18.5 |

3500*865*1715 |

5-6 |

300 |

sixty thousand |

KQ-KG-LY-400 |

22 |

4500*900*1800 |

8-10 |

400 |

eighty thousand |

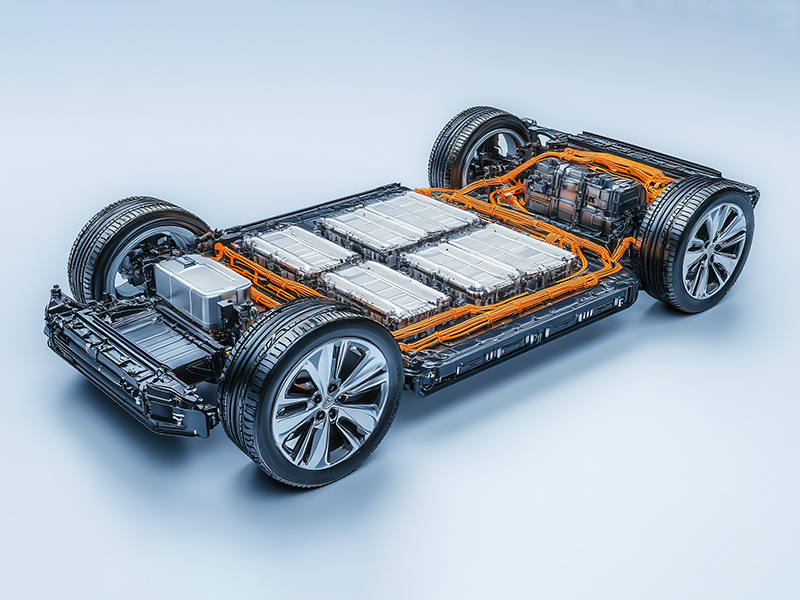

Applicable scenarios

Kitchen waste dewatering, fiber-containing material dewatering, organic matter dewatering, pulp dewatering, Chinese medicine extract dewatering