Kitchen Countertop Process Water

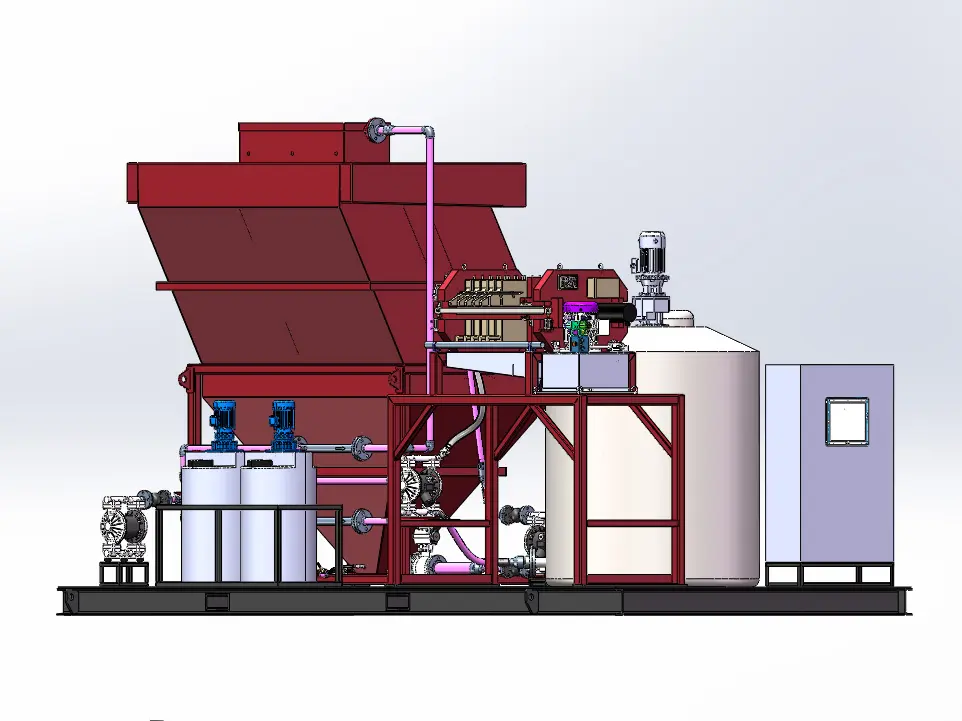

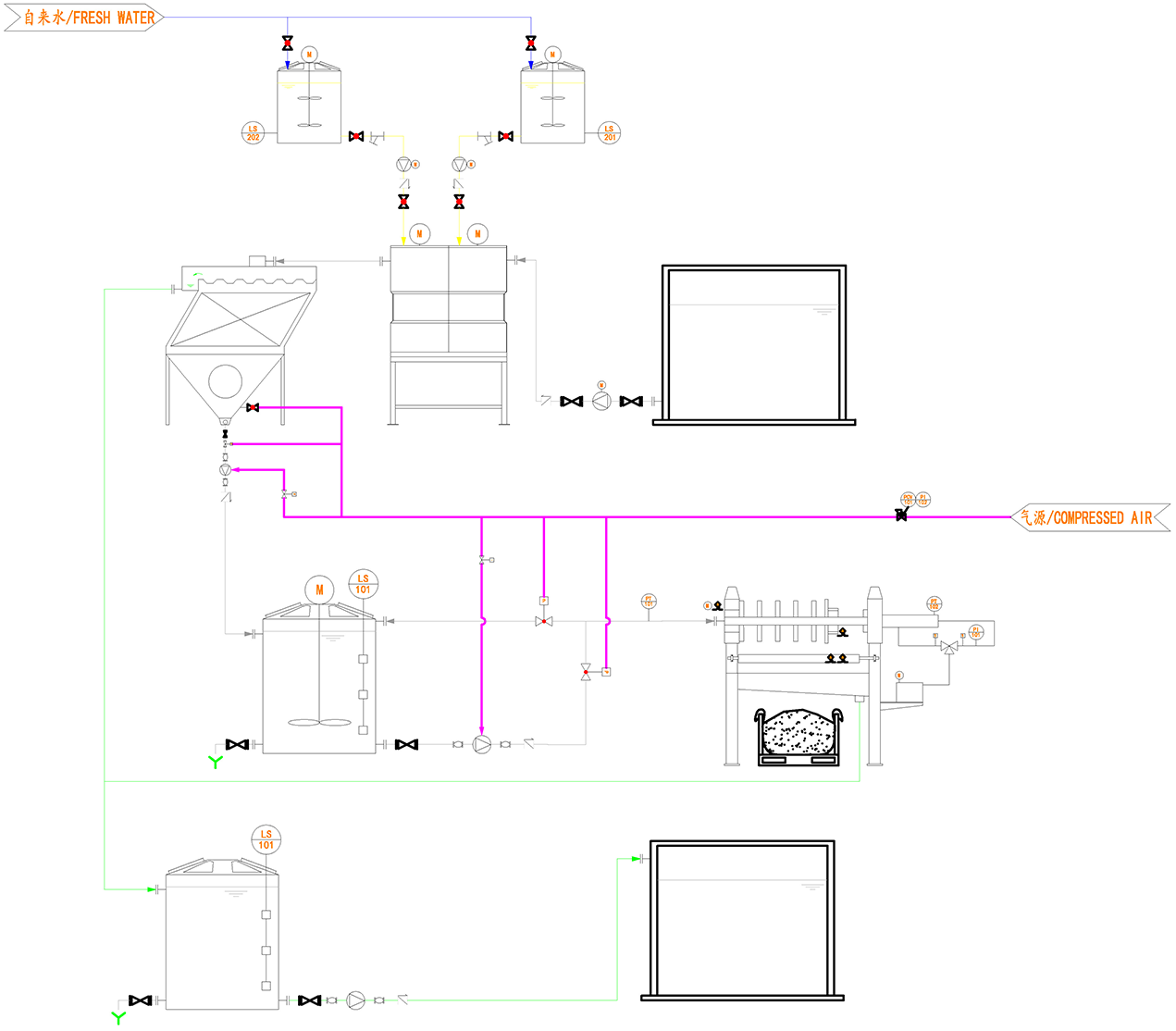

Process flow diagram

Equipment list

Capacity 5-75m³/h

Name |

Basic system |

Quantity |

Senior system |

Quantity |

Full system |

Quantity |

System Description |

Reaction system |

Feeding pump |

1 unit |

Feeding pump |

1 unit |

Feeding pump |

2 units |

The reaction system mainly doses right chemicals such as coagulants and coagulants to the sludge to induce flocculation of the sludge particles and improve their dewatering properties. |

Pipeline mixers |

2 pieces |

MR reaction cell |

1 set |

MR reaction cell |

1 set |

||

PAM dosing drum |

1 piece |

PAM dosing drum |

2 pieces |

PAM integrated dosing device |

1 set |

||

PAM dosing pump |

1 unit |

PAM dosing pump |

1 unit |

PAM dosing pump |

2 units |

||

PAC dosing drum |

1 piece |

PAC dosing drum |

2 pieces |

PAC dosing drum |

2 pieces |

||

PAC dosing pump |

1 unit |

PAC dosing pump |

1 unit |

PAC dosing pump |

2 units |

||

Flowmeter |

/ |

Flowmeter |

/ |

Flowmeter |

1 piece |

||

Sedimentation system |

VMC |

1 unit |

VMC |

1 unit |

VMC |

1 unit |

The sedimentation system is mainly for thickening the effluent and facilitating filter presses. |

Pneumatic Drainage Valve |

1 piece |

Pneumatic Drainage Valve |

1 piece |

Pneumatic Drainage Valve |

1 piece |

||

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

||

Water reuse systems |

Water collection tanks |

1 piece |

Water collection tanks |

1 piece |

Water collection tanks |

1 piece |

The water collection system is mainly to reuse the supernatant after concentration to reduce cost and save money. |

Drainage pump |

1 unit |

Drainage pump |

1 unit |

Drainage pump |

2 units |

||

Filtration system |

Mixing tanks |

1 piece |

Mixing tanks |

1 piece |

Mixing tanks |

1 piece |

The main function of the filter press system is solid-liquid separation |

Feeding pump |

1 unit |

Feeding pump |

1 unit |

Feeding pump |

2 units |

||

KMP |

1 set |

KMP |

1 set |

KMP |

1 set |

||

Control system |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

The automation of all our equipment will be integrated into this system and will be fully automated. |

Accessaries |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Cables and pipe and valve fittings required within the system, depending on the customer's site. |

Please request a detailed list of system from our sales consultant.

Function comparison

Function |

Basic system |

Senior system |

Full system |

Fully automated control |

√ |

√ |

√ |

Faulty alarm |

√ |

√ |

√ |

Automatic reaction vessels |

- |

√ |

√ |

Automatic standby switchover |

- |

- |

√ |

Automatic dosage adjustment |

- |

- |

√ |

Inverter control or not |

- |

- |

√ |

Time between infusions |

4 hours |

8 hours |

Fully automatic |

Optional features

Serial number |

Name |

Specifications |

Function |

1 |

Special anti-corrosion |

FRP Coating for the liquid connection parts |

Prevents corrosion from high acids, salts, fluorine, etc. |

2 |

Special materials |

304/316L etc. |

According to the user's material characteristics |

3 |

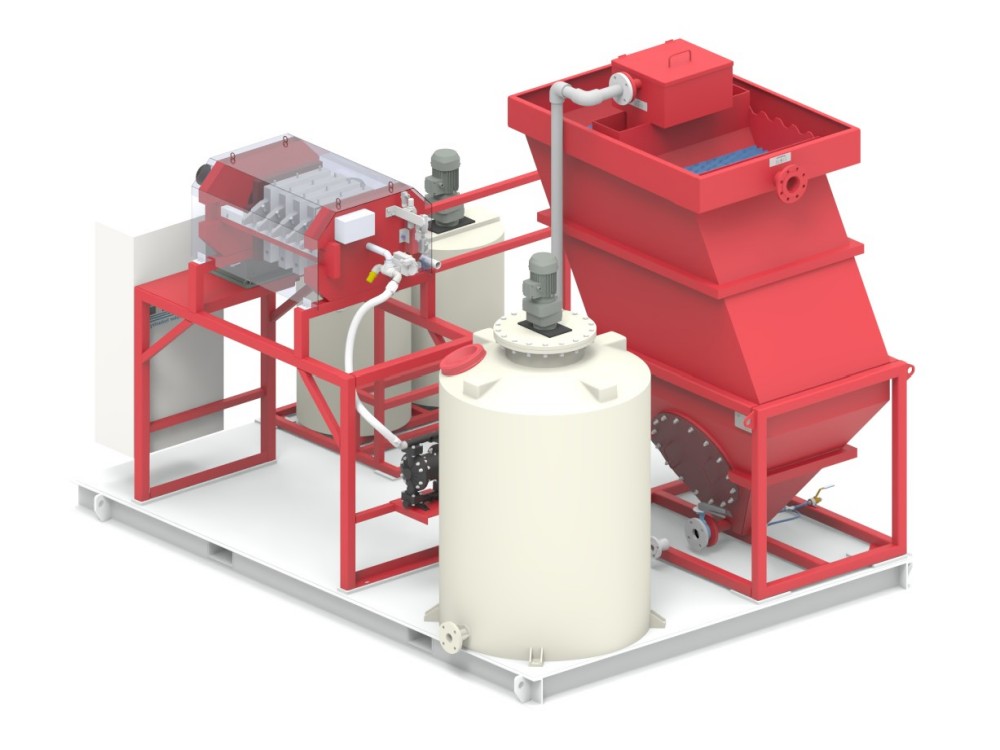

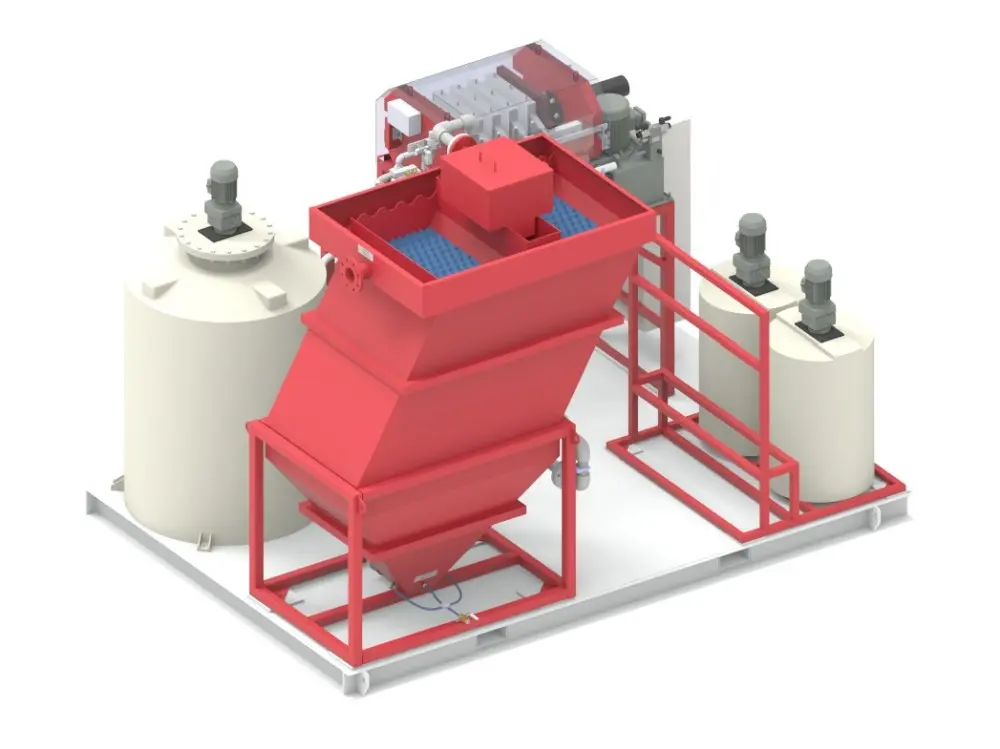

Skid mounted |

Patterned steel platform + fixed bracket + wire channel, piping, cables, etc. |

Easy to install, transport and flexible to move |

4 |

PH automatic adjustment |

PH online monitoring + integrated control + acid and alkali dosing system |

Enables the effluent water to reach the standard PH value. |

5 |

Precision filters |

Containing multi-stage centrifugal pumps |

Reducing the suspended solids content of filtrate and regulating water quality |

6 |

Flameproof |

DIIBT4/CT4 etc. |

Electrical components, motors, etc. placed in explosion-proof areas are classified according to different levels. |

7 |

Conveyor systems/staging systems |

Conveyor / Hopper |

Mud cake can be collected by conveying equipment or staging systems, reducing labour. |

Product Introduction

Kitchen Countertop Process Water is characterized by several distinctive features that demand careful management. Firstly, it often contains a high concentration of fine particles, primarily derived from the abrasion of countertop materials during cutting and polishing processes. These suspended solids can significantly increase the turbidity of the water, reducing its clarity and potentially causing blockages in pipelines and processing equipment if not properly filtered.

In terms of pH, Kitchen Countertop Process Water typically has an alkaline nature, usually ranging from 8 to 11. This alkalinity stems from the chemical compounds present in the countertop materials, such as certain minerals in natural stone, and the additives used in the manufacturing process, like setting agents and surface treatment chemicals. An improper pH level can not only affect the performance of the processing equipment but also influence the chemical reactions involved in surface finishing and bonding processes, potentially compromising the quality of the final product.

Another concerning aspect is the possible presence of heavy metals. Depending on the type of countertop materials, Kitchen Countertop Process Water may carry traces of heavy metals like lead (Pb), cadmium (Cd), and mercury (Hg). These heavy metals can originate from the raw materials themselves or from the machinery and tools used in the production line. Even in low concentrations, they pose a significant threat to the environment and human health if released untreated, as they can accumulate in soil and water bodies, entering the food chain and causing long - term ecological and health issues.

The water also shows elevated levels of chemical oxygen demand (COD) and biological oxygen demand (BOD). This is mainly due to the introduction of organic substances such as lubricants, coolants, and cleaning agents used during the manufacturing process. These organic pollutants not only consume oxygen in water bodies when discharged, leading to hypoxic conditions that are harmful to aquatic life, but they can also leave residues on the countertop surface if not adequately removed, affecting its appearance and functionality.

Moreover, Kitchen Countertop Process Water usually has high hardness, primarily caused by the dissolution of calcium and magnesium ions from the countertop materials, especially those made from natural stone or composite materials with calcareous components. High - hardness water can lead to the formation of scale deposits in pipes and equipment, reducing their efficiency and lifespan. It can also interfere with the effectiveness of some chemical treatments used in the manufacturing process.

Finally, the presence of oil and grease residues is common in Kitchen Countertop Process Water. These residues come from the lubricating oils used in machinery, as well as the release agents and protective coatings applied to the countertops. If not properly removed, oil and grease can form a film on the water surface, preventing oxygen exchange and causing unpleasant odors. They can also contaminate soil and vegetation if the water is disposed of improperly, disrupting the local ecological balance.