VMC

Technical characteristics

Product features and advantages:

Small footprint, high precipitation efficiency.

High integration, easy to install.

Simple operation, maintenance and cleaning.

0.8mm thickened PVC material to ensure the strength and service life of the inclined pipe.

Industry application

Applicable industry:

Material processing, industrial ceramics, glass processing, metal cutting, photovoltaic, semiconductor, seawater desalination, coal washing, municipal, etc.

Processing capacity and parameters

Model |

Flow rate (m³/h) |

Dimension L*W*H(mm) |

Weight (kg) |

Volume (m³) |

VMC10 |

5 |

1910*1135*2180 |

740 |

1.74 |

VMC20 |

10 |

1985*1860*2515 |

1172 |

3.9 |

VMC30 |

15 |

2415*2000*2500 |

1389 |

5.13 |

VMC40 |

20 |

3000*2000*2800 |

1685 |

7.28 |

VMC60 |

30 |

3020*2760*2850 |

2150 |

10.3 |

VMC100 |

50 |

4760*3010*3030 |

4354 |

29.4 |

VMC150 |

75 |

6700*3050*3860 |

7537 |

41.1 |

VMC200 |

100 |

7400*3280*3900 |

8160 |

44.73 |

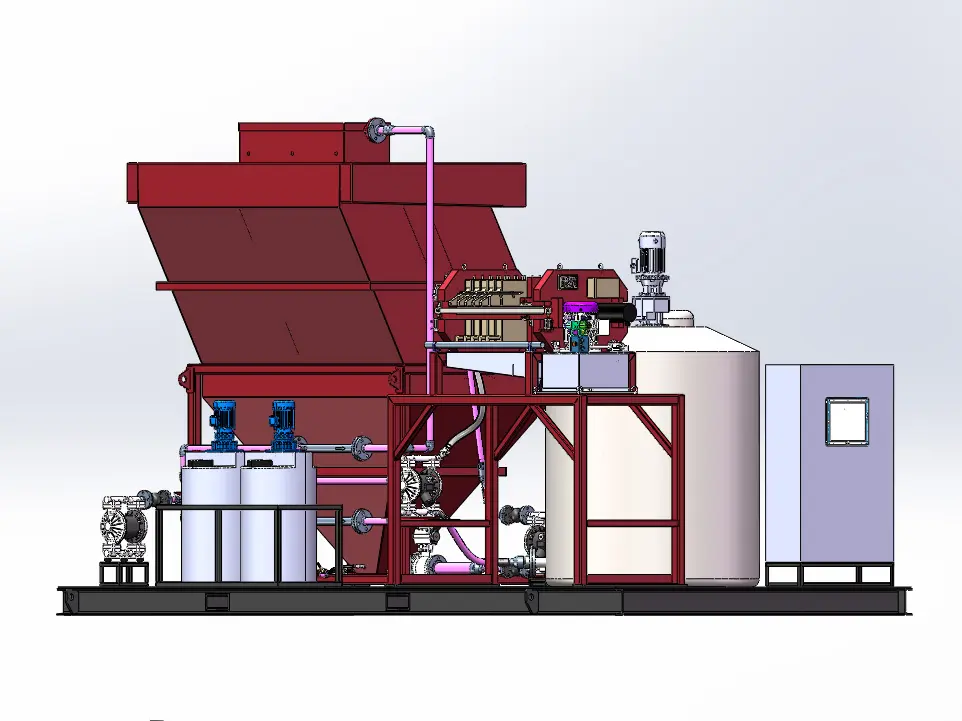

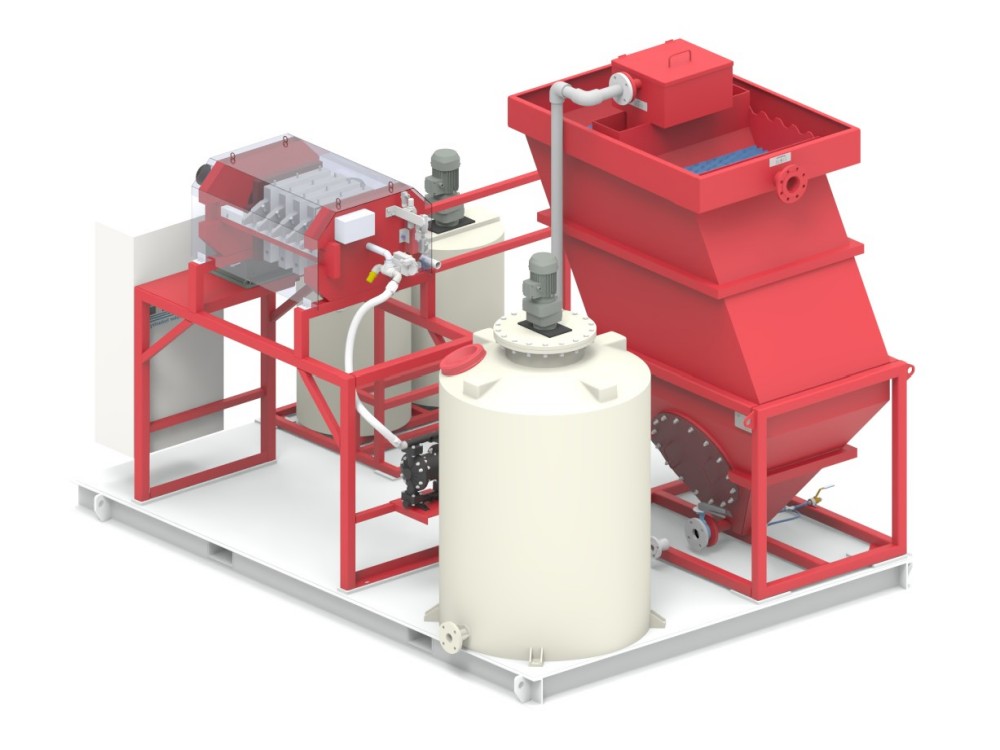

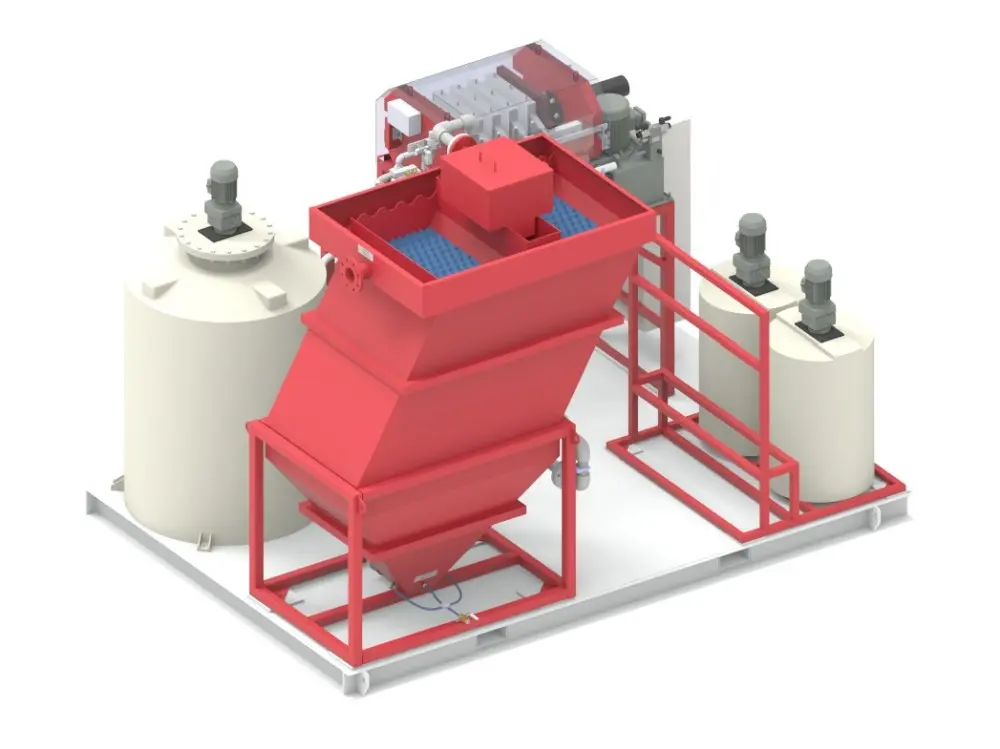

Product Introduction

The Lamellar Clarifier (VMC), also commonly referred to as the inclined plate/tube settler, represents a remarkable advancement in water treatment technology. Rooted in the groundbreaking "Shallow Tank Theory" put forth by German Professor Hazen, this innovative device redefines the principles of sedimentation. At its core, the Lamellar Clarifier features a strategic installation of a series of inclined plates or tubes within the sedimentation tank. This unique design is not merely an engineering feat but a revolutionary concept. By incorporating these inclined structures, the effective settling area of the tank is exponentially increased. It's like multiplying the available space for particles to settle without expanding the physical footprint of the tank itself. This ingenious approach also significantly improves the hydrodynamic conditions inside the tank. Instead of large, turbulent water flows that can disrupt the settling process, the inclined plates or tubes create a more controlled and laminar flow environment. As a result, sedimentation efficiency soars to new heights, allowing for a much faster and more effective separation of solids from liquids.

The Lamellar sedimentation process is a well - orchestrated symphony of five distinct stages.

Filtration & energy dissipation

Uniform water distribution

Solid-liquid separation

Clarified water collection

Sludge thickening

To further enhance its functionality, the Lamellar Clarifier offers flexibility based on varying water quality requirements. For situations where sludge accumulation is significant, a bottom - mounted sludge scraper can be installed. This addition optimizes sludge discharge conditions, ensuring that the settled sludge is efficiently removed from the tank. Whether it's treating municipal wastewater, industrial effluents, or water for drinking purposes, the Lamellar Clarifier has proven itself as a reliable and highly effective solution, combining theoretical innovation with practical engineering excellence.