KMP/KRP

Technical characteristics

Product features and advantages:

Small footprint, short filtration time, high efficiency.

High integration, easy to install.

Simple operation, maintenance and cleaning.

100% acrylic filter plate, reduce the pressure of filter cloth.

Industry application

Applicable industry:

Stone processing, industrial ceramics, glass processing, metal cutting, photovoltaic, semiconductor, seawater desalination, coal washing, municipal, etc.

Processing capacity and parameters

KMP

Model |

Specification (L*W*Hmm) |

Net weight (kg) |

Filtering area (㎡) |

Volume (L) |

Total power (KW) |

KMP400/5 |

2300*900*2000 |

890 |

1.16 |

14.4 |

0.75 |

KMP500/5 |

2300*1000*2000 |

1140 |

1.7 |

23.76 |

0.75 |

KMP500/8 |

2600*1000*2000 |

1280 |

2.98 |

41.58 |

2.2+0.25 |

KMP630/8 |

2700*1200*2200 |

1360 |

4.76 |

62.3 |

2.2+0.25 |

KMP630/12 |

3400*1200*2200 |

1500 |

7.48 |

97.9 |

2.2+0.25 |

KMP800/15 |

4000*1350*2350 |

2900 |

15.12 |

215.6 |

2.2+0.25 |

KRP

Model |

Specification (L*W*Hmm) |

Net weight (kg) |

Filtering area (㎡) |

Volume (L) |

Total power (KW) |

KRP500/5 |

2600*1100*2600 |

1700 |

1.7 |

23.76 |

2.2+0.25 |

KRP500/8 |

3000*1100*2700 |

1850 |

2.98 |

41.58 |

2.2+0.25 |

KRP630/8 |

3000*1200*3000 |

2150 |

4.76 |

62.3 |

2.2+0.25 |

KRP630/12 |

3600*1200*3000 |

2360 |

7.48 |

97.9 |

2.2+0.25 |

KRP800/15 |

4700*1600*2400 |

3500 |

15.12 |

215.6 |

2.2+0.25 |

KRP800/25 |

6700*1700*2300 |

5150 |

25.92 |

369.8 |

4+0.25 |

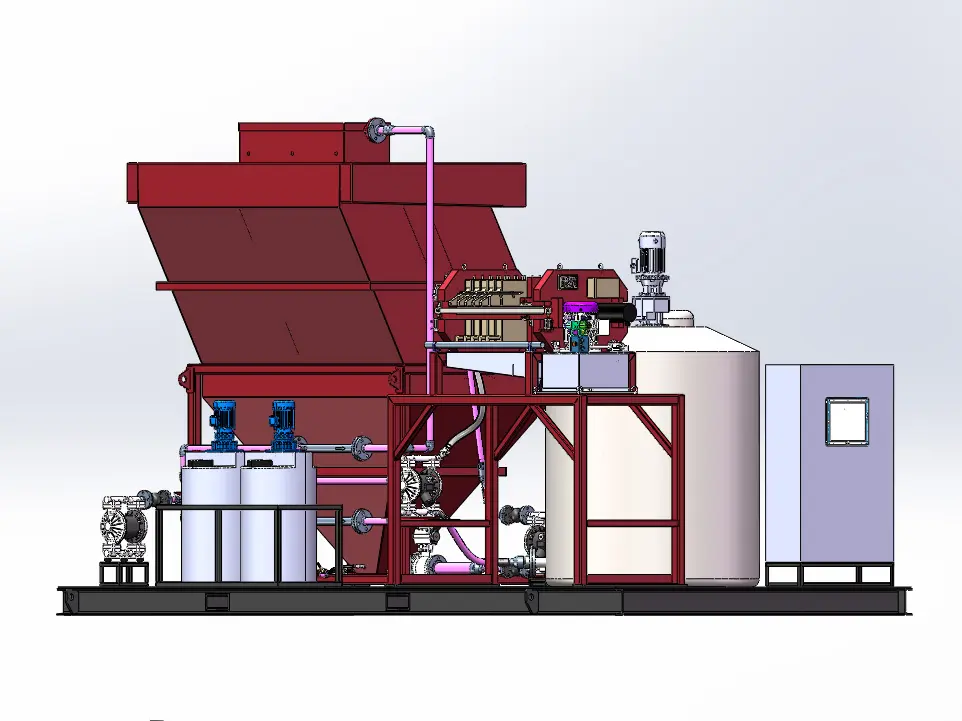

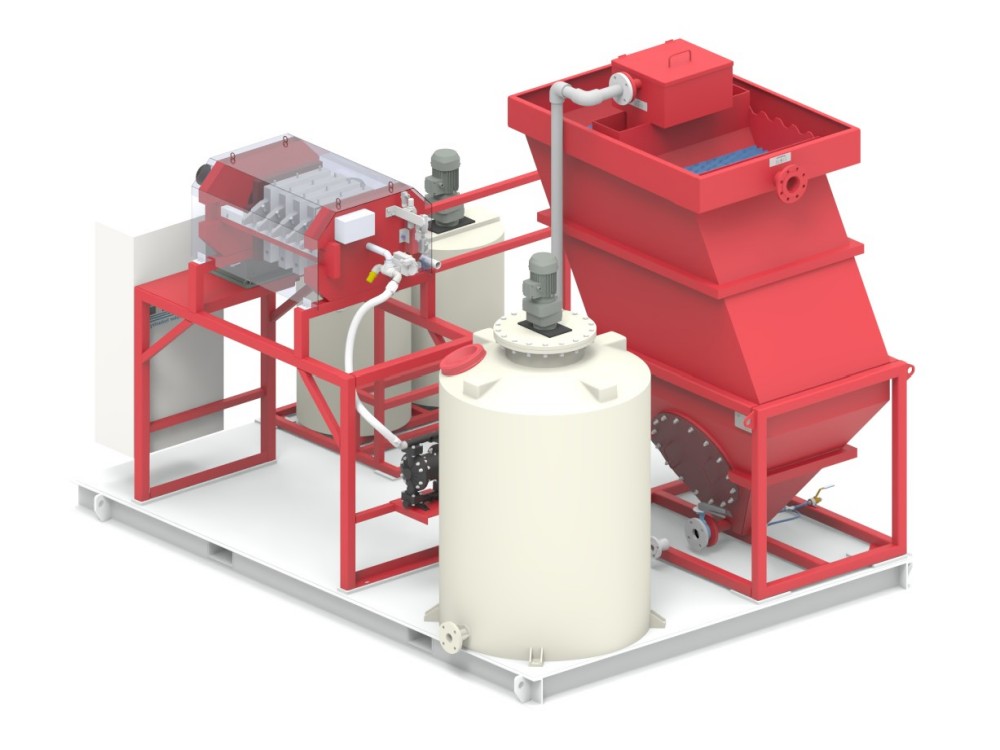

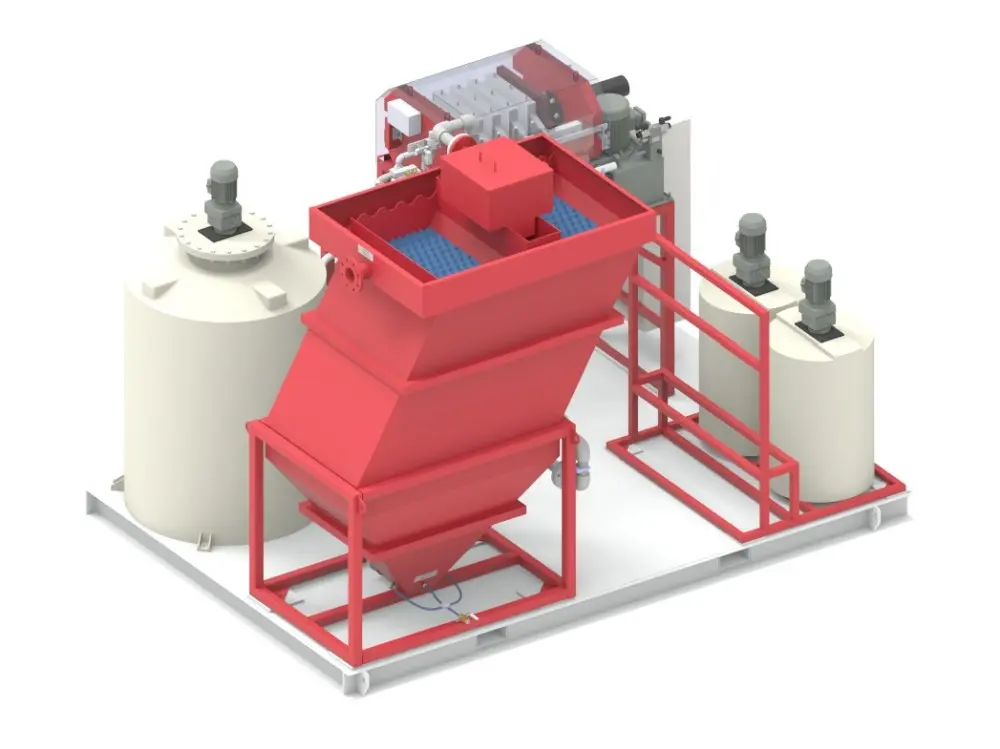

Product Introduction

The KMP/KRP filter press system stands at the forefront of industrial separation technology, boasting advanced rapid solid - liquid separation capabilities. Originating from cutting - edge German engineering, this technology has been carefully integrated into the system, ensuring unparalleled precision and efficiency in separating solids from liquids. The equipment itself is a marvel of modern design, featuring a uniquely crafted quick - opening enclosed structure. This innovative design not only simplifies the maintenance and operation process but also significantly reduces the risk of leakage and contamination, safeguarding the integrity of the separation process.

The KMP/KRP system is a fully automated powerhouse, seamlessly integrating a comprehensive suite of functions. Press filtration, the core process, is executed with utmost accuracy, applying optimal pressure to extract maximum liquid from the sludge or slurry. The filter plate vibration function shakes off stubborn solids adhering to the plates, ensuring thorough cake discharge. The automated valve opening and closing mechanisms precisely control the flow of materials, while the material pump start/stop functions operate in harmony to maintain a consistent and efficient workflow. Material detection sensors continuously monitor the process, providing real - time data, and the fault alarm system promptly alerts operators to any issues, minimizing downtime.

Understanding that every customer has unique needs, PWI offers a range of customized solutions. Automatic liquid collection drip trays are designed to capture and contain any spills, keeping the working environment clean and safe. Electric vibratory plates are available to assist with the cake discharge process, especially for more viscous or sticky materials. Additionally, high - pressure spray cleaning systems for filter plates and cloths ensure thorough cleaning, extending the lifespan of the components and maintaining optimal performance.

With a steadfast commitment to innovation, PWI endeavors to provide users with a new generation of sludge dewatering equipment. The KMP/KRP filter press system not only offers higher efficiency, reducing processing time and increasing throughput, but also ensures cleaner operation, minimizing environmental impact. Enhanced safety features protect operators from potential hazards, while the smarter performance, enabled by advanced automation and monitoring, allows for seamless integration into modern industrial processes.