Glass Grinding and Polishing Pocessing Water

Features

Wastewater classification

1. Saw blade cutting wastewater (sawing machine wastewater)

The main pollutants of glass processing wastewater are "coolant" and saw blade cooling water. Generally, the main components of coolant are resin acid and its saponification products, unsaturated fatty acids and their saponification products, lignin and its degradation products, etc. Resin acid is mainly rosin acid and hippocampal acid, etc.

2. Grinding wastewater and trimming machine wastewater

After the raw materials are processed, the surface of the board usually needs to be further processed, and there will be a lot of dust pollutants during the processing. In order to reduce pollution, water is usually used as an auxiliary dust removal agent.

The water consumption of the glass deep processing industry is mainly in the pretreatment process, including edge grinding, drilling cooling water and washing water. The wastewater generated in the pretreatment process contains a large amount of glass silica powder and a small amount of silica powder, corundum grit, cutting kerosene, cleaning agent and citric acid. Therefore, the wastewater volume is large, the concentration of glass powder is high, and it is difficult to biodegrade. In addition, there are some additives and oils in the water, and the wastewater is generally acidic.

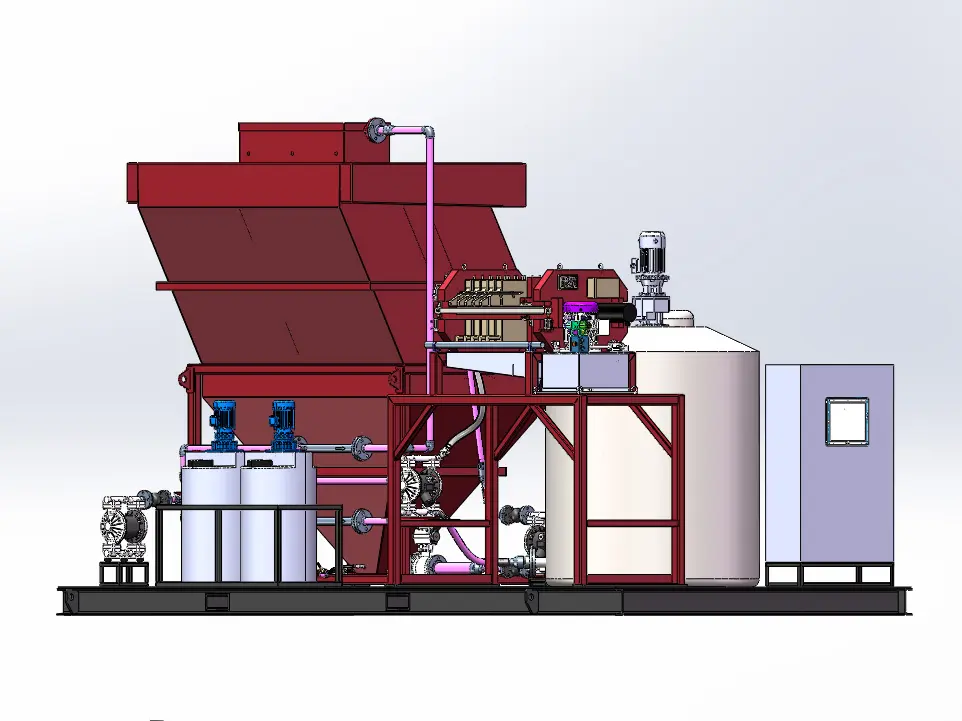

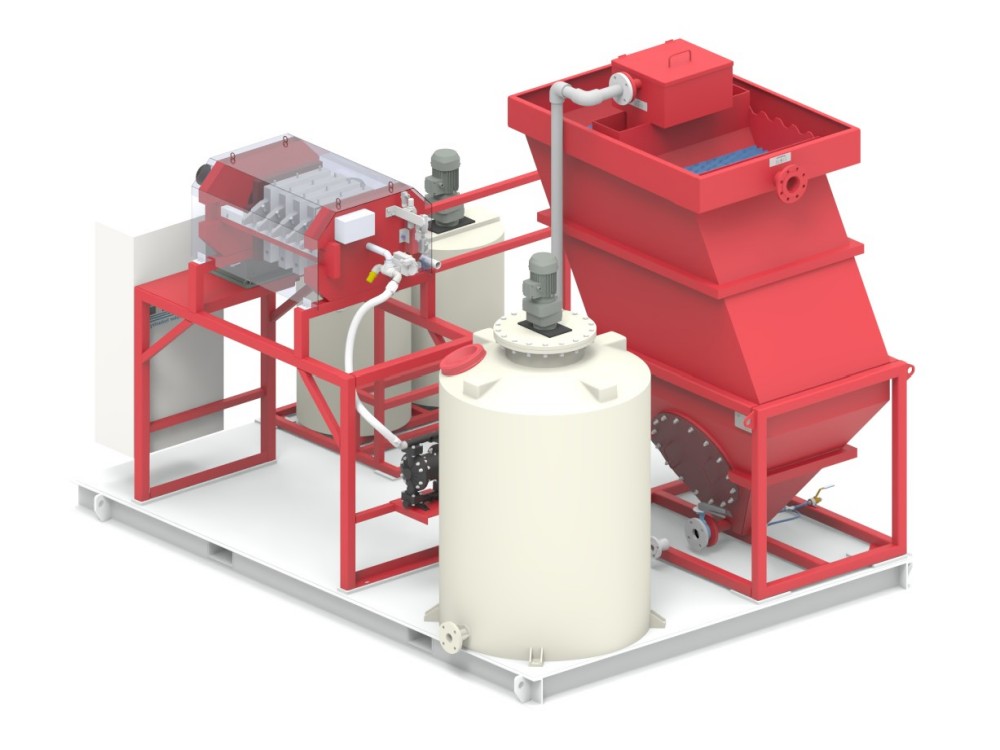

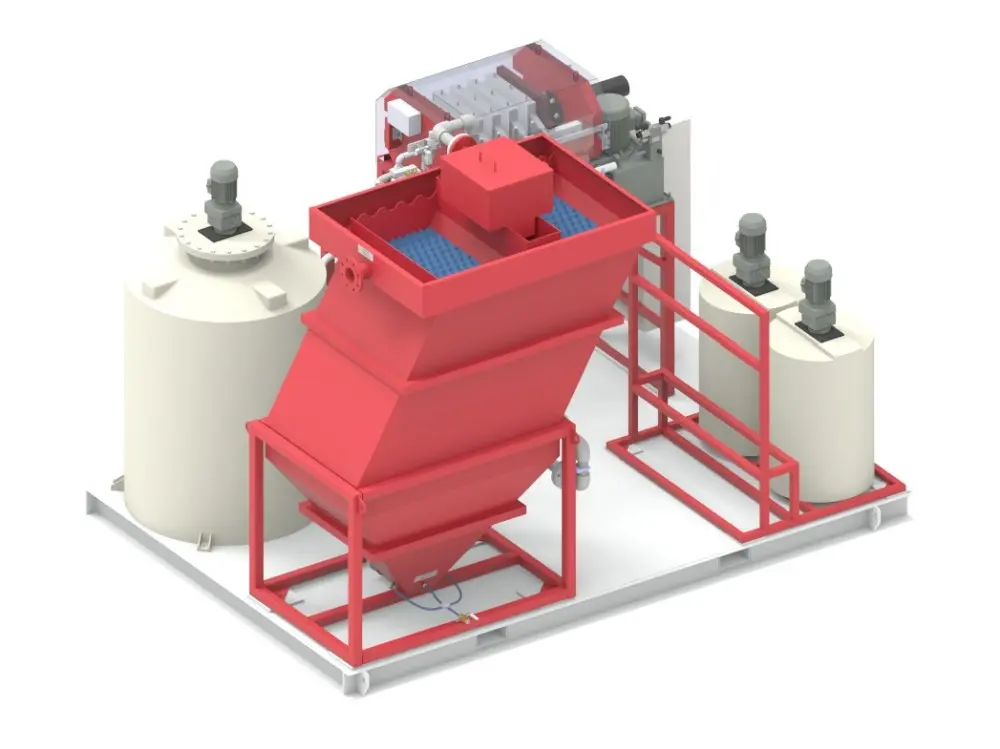

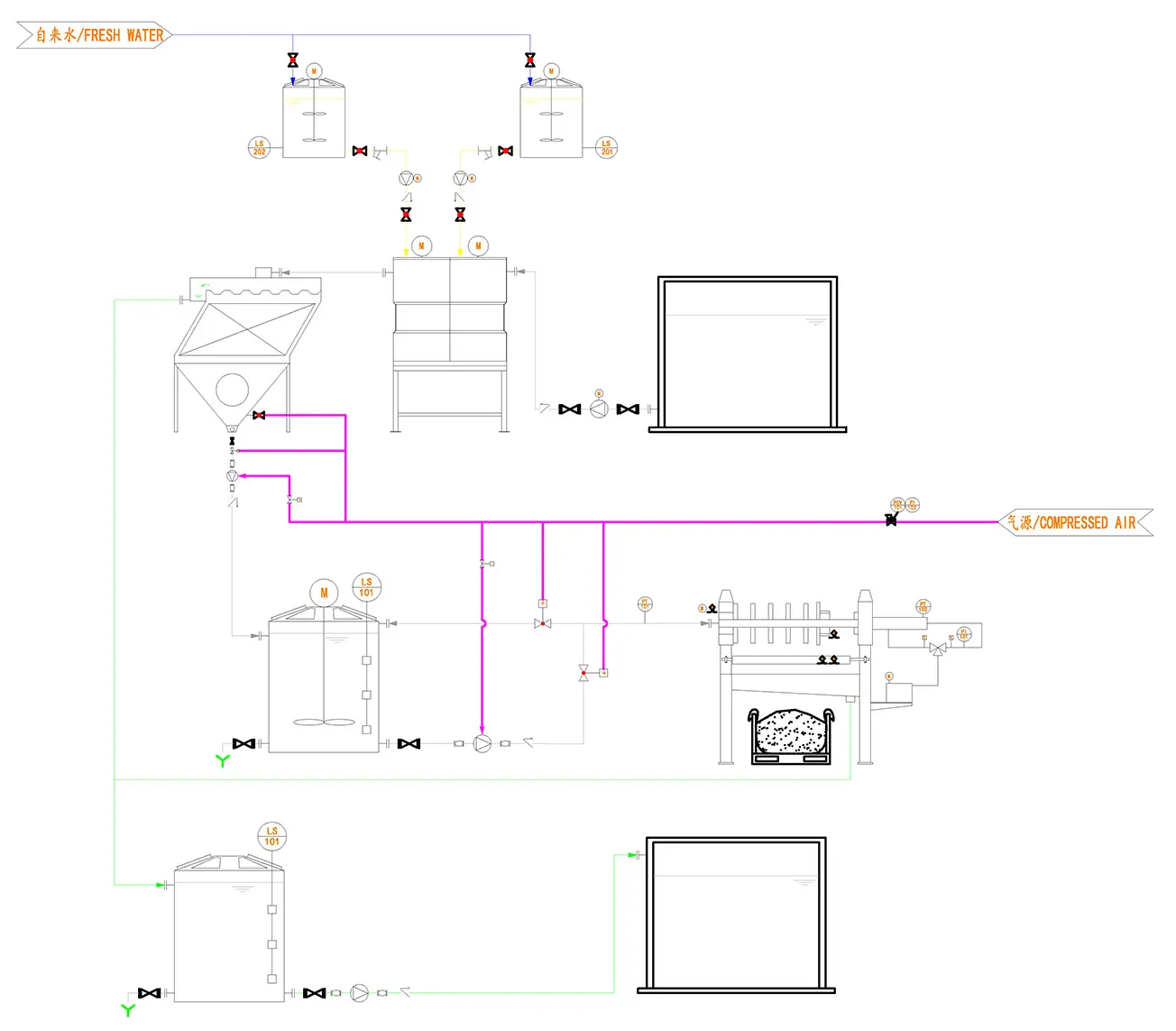

Process flow chart

Configuration Table

Sewage treatment capacity 5-75m³/h

name |

Basic Configuration |

quantity |

Upgrade Configuration |

quantity |

Complete Configuration |

quantity |

System Description |

Reaction system |

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

The reaction system mainly adds chemical agents such as coagulants and coagulants to the sludge to promote flocculation of sludge particles and improve its dewatering performance. |

Pipeline mixer |

2 |

MR reaction pool |

1 set |

MR reaction pool |

1 set |

||

PAM dosing tank |

1 |

PAM dosing tank |

2 |

PAM integrated dosing device |

1 set |

||

PAM dosing pump |

1 unit |

PAM dosing pump |

1 unit |

PAM dosing pump |

2 units |

||

PAC dosing tank |

1 |

PAC dosing tank |

2 |

PAC dosing tank |

2 |

||

PAC dosing pump |

1 unit |

PAC dosing pump |

1 unit |

PAC dosing pump |

2 units |

||

Electromagnetic flowmeter |

/ |

Electromagnetic flowmeter |

/ |

Electromagnetic flowmeter |

1 |

||

Sedimentation system |

VMC Sedimentation Tank |

1 unit |

VMC Sedimentation Tank |

1 unit |

VMC Sedimentation Tank |

1 unit |

The sedimentation system is mainly used to concentrate sewage and facilitate filter pressing. |

Pneumatic mud valve |

1 |

Pneumatic mud valve |

1 |

Pneumatic mud valve |

1 |

||

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

||

Recycled water reuse system |

Grey water collection barrel |

1 |

Grey water collection barrel |

1 |

Grey water collection barrel |

1 |

The grey water collection system is mainly used to reuse the concentrated supernatant to reduce costs and save expenses. |

Drain pump |

1 unit |

Drain pump |

1 unit |

Drain pump |

2 units |

||

Filter press system |

Homogenizing mixing tank |

1 |

Homogenizing mixing tank |

1 |

Homogenizing mixing tank |

1 |

The main function of the filter press system is solid-liquid separation |

Feed pump |

1 unit |

Feed pump |

1 unit |

Feed pump |

2 units |

||

KMP filter press |

1 set |

KMP filter press |

1 set |

KMP filter press |

1 set |

||

Control System |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

All the automation controls of our equipment will be integrated into this system and run fully automatically |

Supplementary materials |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

The specific quantity of cables, pipes and valves required within the system depends on the customer's on-site conditions. |

Please ask our sales consultant for a detailed system configuration list.

Feature Comparison

Function |

Basic Configuration |

Upgrade Configuration |

Complete Configuration |

Fully automated control |

√ |

√ |

√ |

Fault alarm |

√ |

√ |

√ |

Automatic reaction vessel |

- |

√ |

√ |

Automatic standby switching |

- |

- |

√ |

Automatic adjustment of dosing |

- |

- |

√ |

Whether frequency conversion control |

- |

- |

√ |

Soaking interval time |

4 hours |

8 hours |

Fully automatic |

Optional functions

Serial number |

name |

illustrate |

effect |

1 |

Special anti-corrosion |

Internal liquid contact parts are three-cloth and five-oil glass fiber anti-corrosion |

Prevent corrosion from high acid, high salt, high fluorine, etc. |

2 |

Special materials |

304/316L etc. |

Select according to user material characteristics |

3 |

Overall skid mounted |

Patterned steel platform + fixed bracket + cable duct, pipeline, cable, etc. |

Easy to install, transport and move flexibly |

4 |

PH automatic adjustment |

PH online monitoring + integrated control + acid and alkali dosing system |

Make the effluent reach the standard PH value |

5 |

Fine filter |

Contains multi-stage centrifugal pump |

Reduce the content of suspended solids in the filtrate and adjust the water quality |

6 |

Explosion-proof |

DⅡBT4/CT4 etc. |

Electrical components, motors, etc. placed in explosion-proof areas are divided into different levels |

7 |

Conveying system/temporary storage system |

Conveyor/sludge hopper |

Mud cake can be collected through conveying equipment or temporary storage system, reducing labor |