Actived Carbon Rejuvenation

Characteristics of Wastewater in the Activated Carbon Industry

In the production of activated carbon, wastewater primarily originates from the soaking, washing, and regeneration processes. These wastewaters typically contain large quantities of organic substances, suspended solids, acidic or alkaline compounds, and other chemical pollutants. The main challenges in treating this wastewater include:

High Concentration of Organic Compounds: During the production of activated carbon, wastewater often contains high levels of organic compounds such as dissolved organic matter, surfactants, and other chemical additives, which are difficult to remove using conventional biological treatment methods.

Suspended Solids: The wastewater frequently contains a significant amount of suspended solids, including carbon dust, particles, and other solid materials. These suspended solids not only increase the turbidity of the water but can also affect the efficiency of subsequent treatment processes.

Acidic and Alkaline Compounds: Due to the use of various chemicals during the soaking and washing stages of activated carbon production, the wastewater is often either acidic or alkaline. The presence of strong acids, such as hydrofluoric acid and nitric acid, adds complexity to the treatment process.

Heavy Metal Ions: In the production of certain activated carbon products, catalysts or chemicals containing heavy metals may be used, leading to the presence of heavy metal ions such as lead, cadmium, and copper in the wastewater. These pollutants require specialised treatment to avoid environmental contamination.

High Salinity and Fluoride Ions: During the regeneration process of activated carbon, wastewater may contain elevated concentrations of fluoride ions and salts. These substances not only impact water quality but can also cause corrosion and damage to subsequent treatment systems.

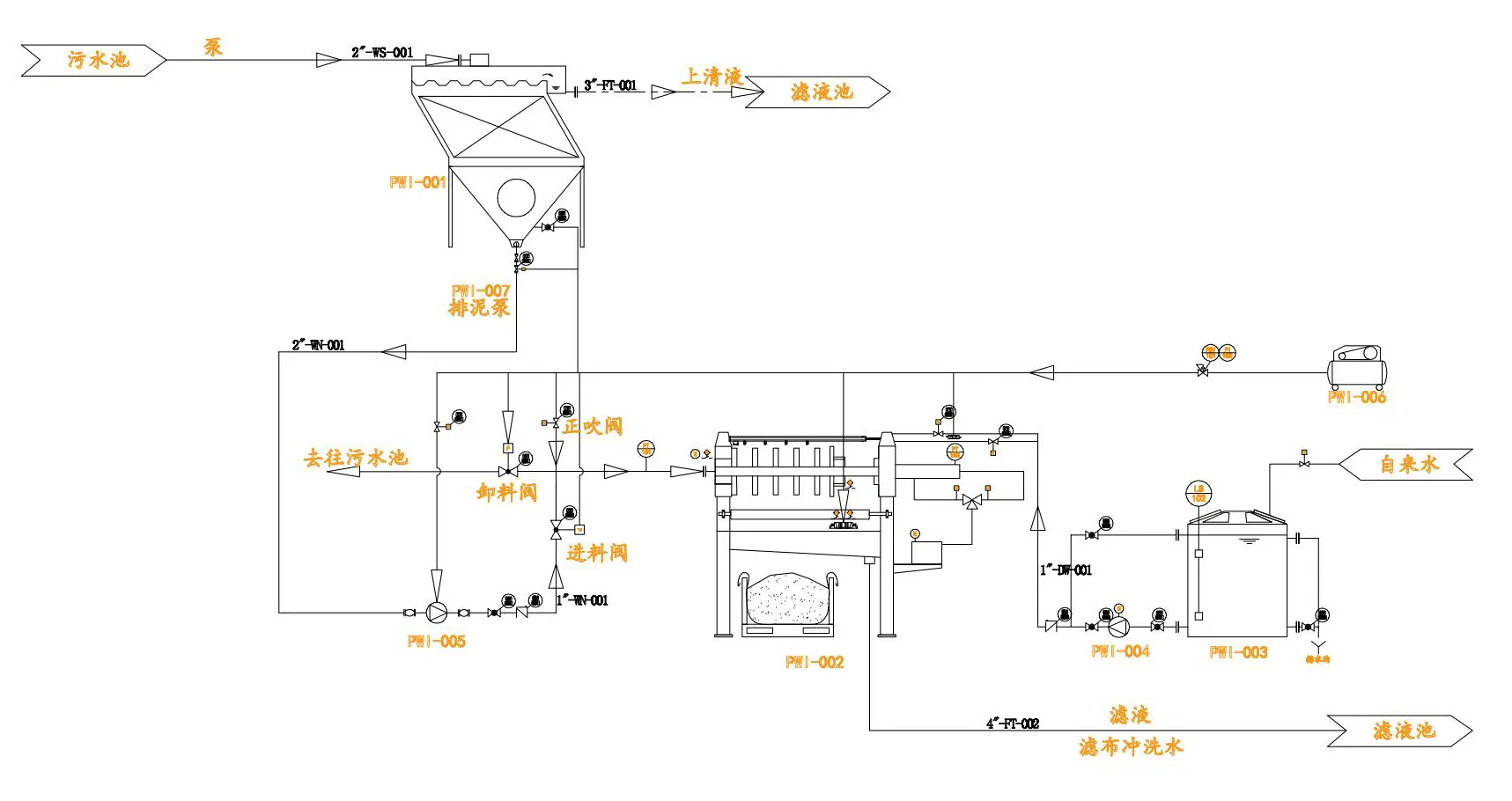

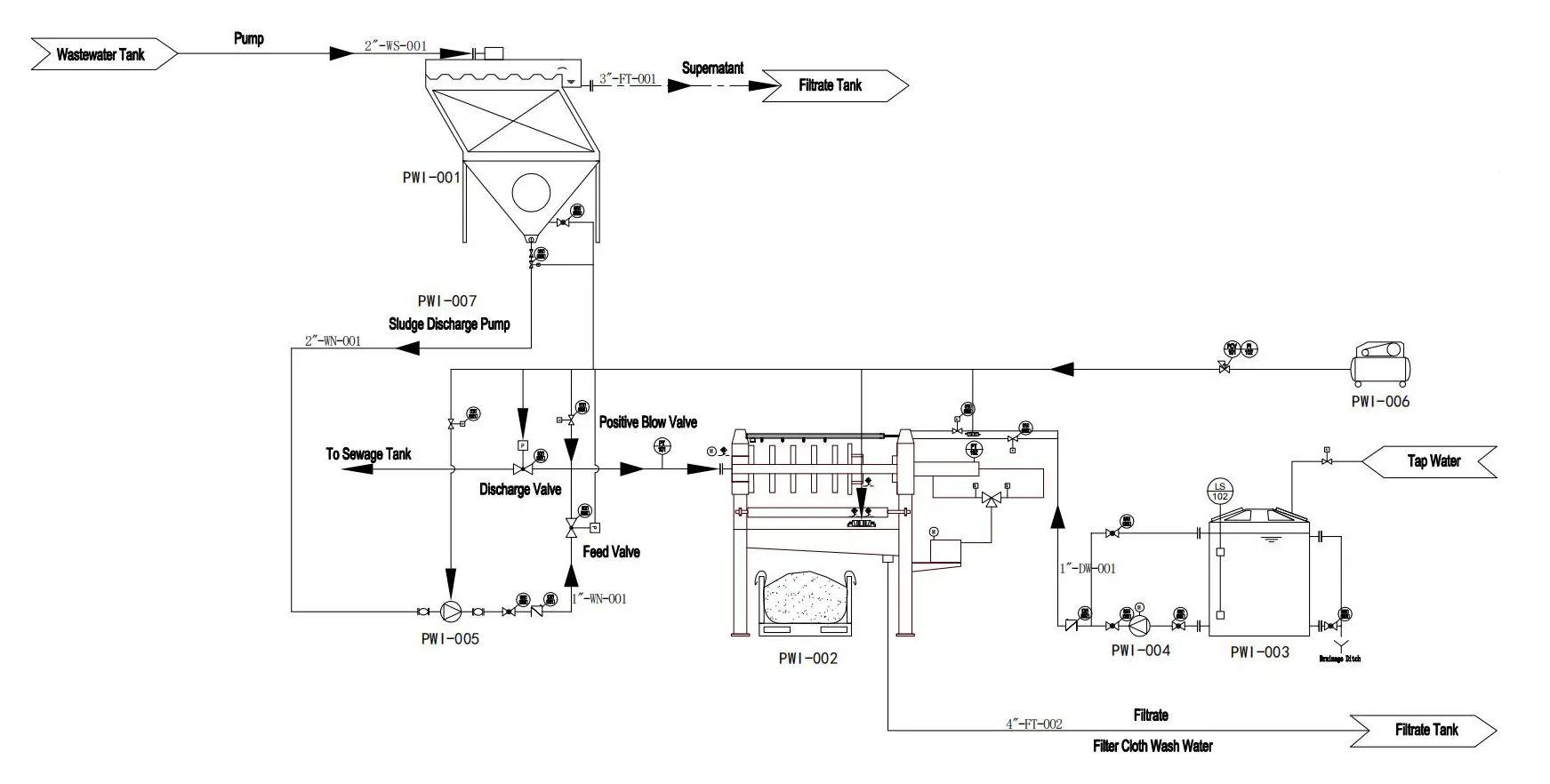

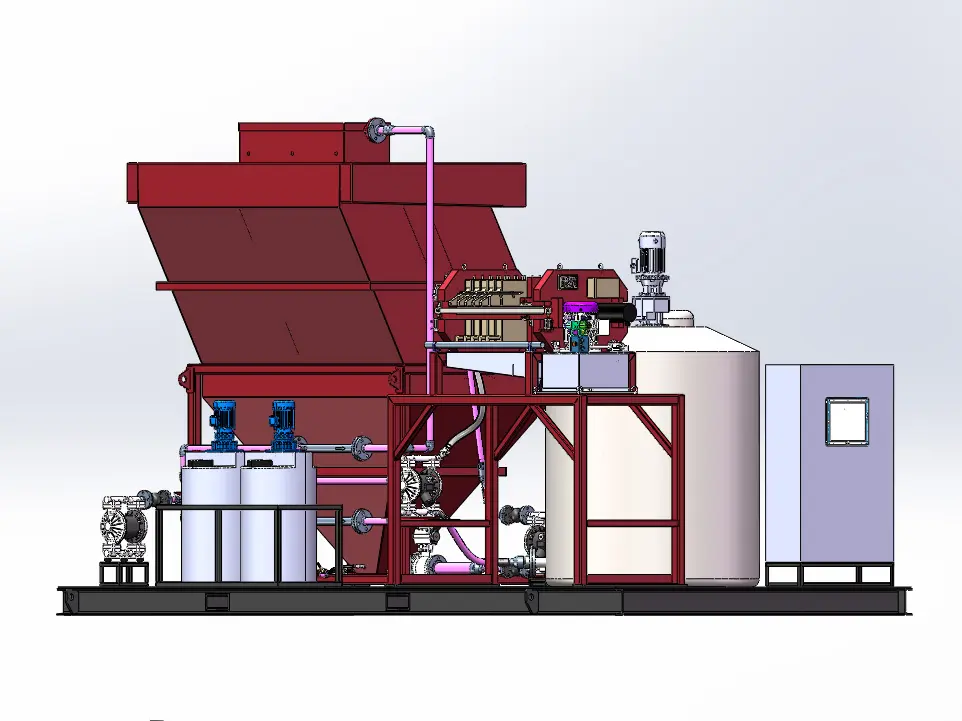

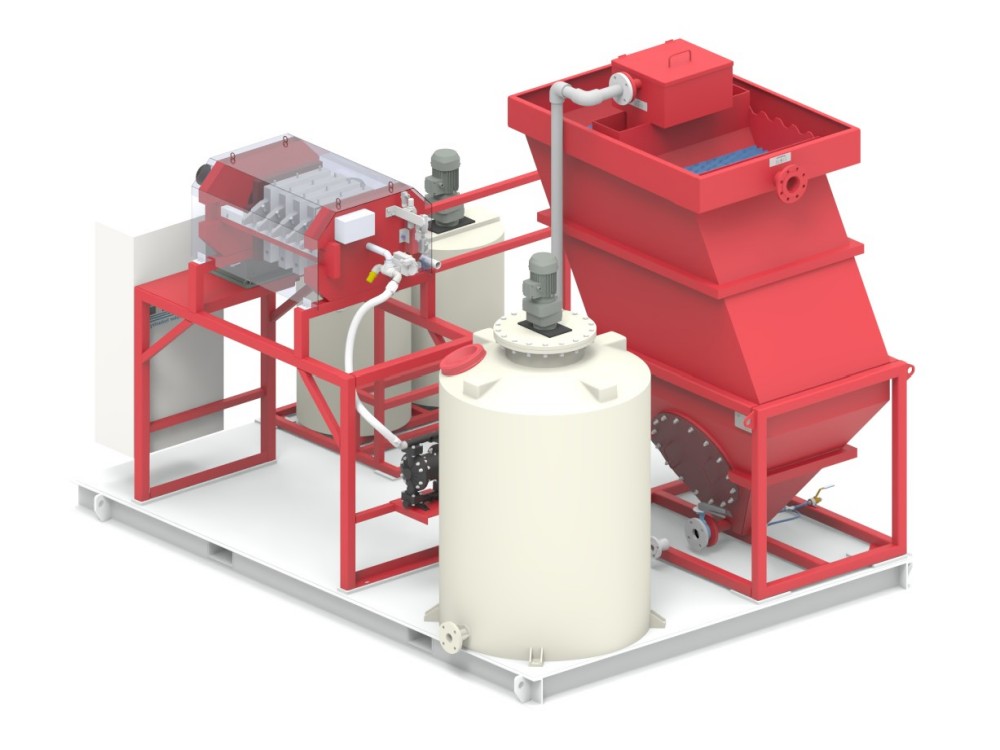

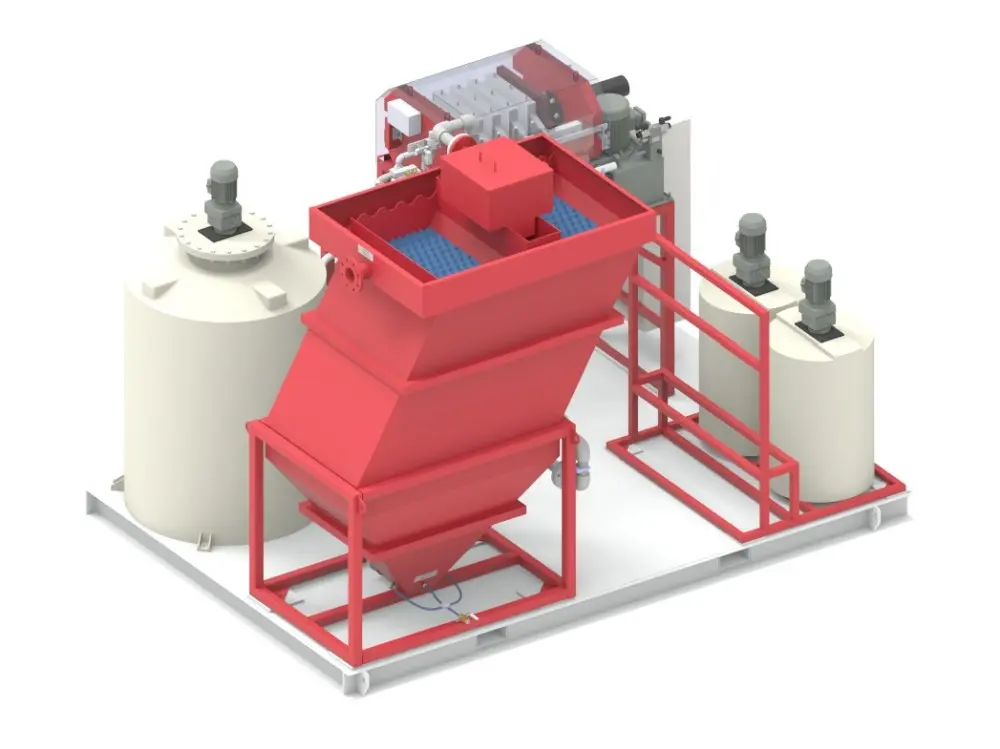

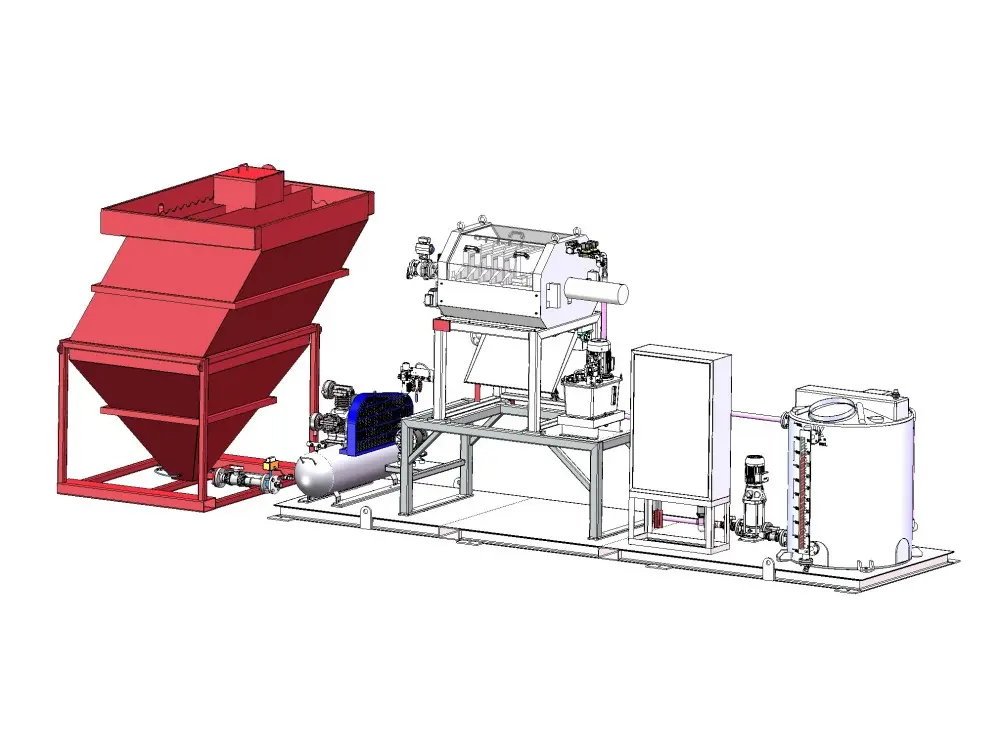

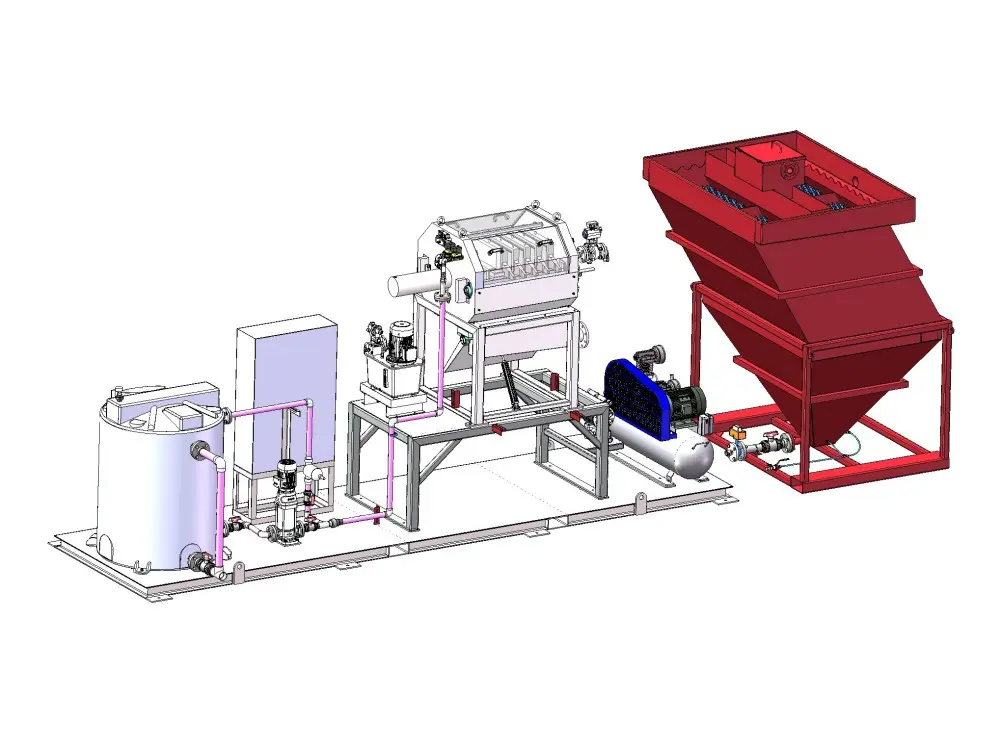

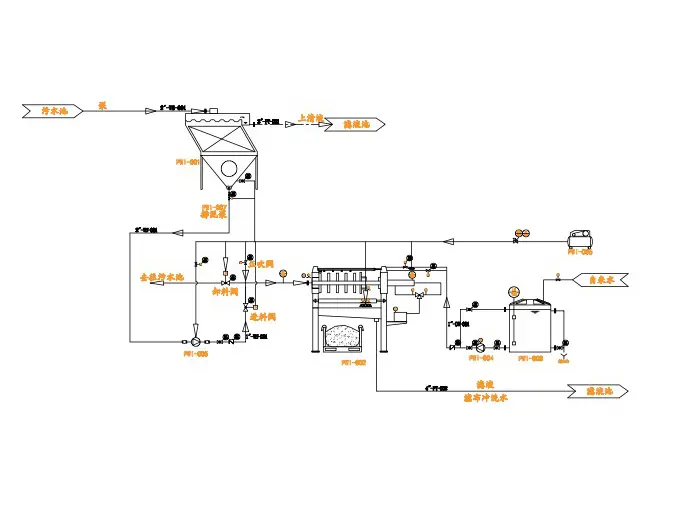

Process flow diagram