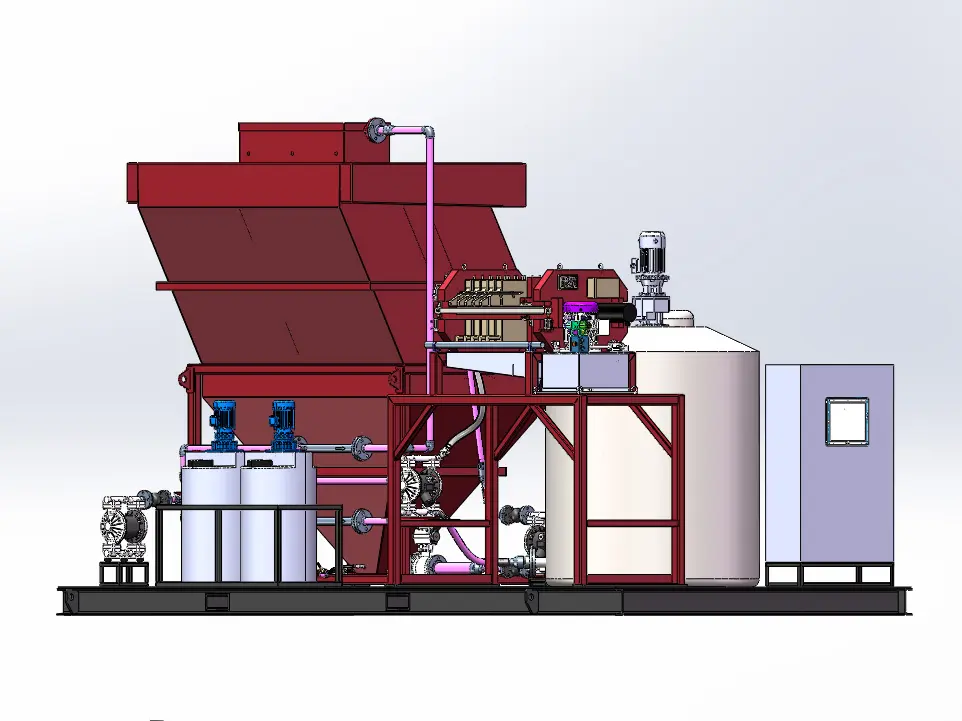

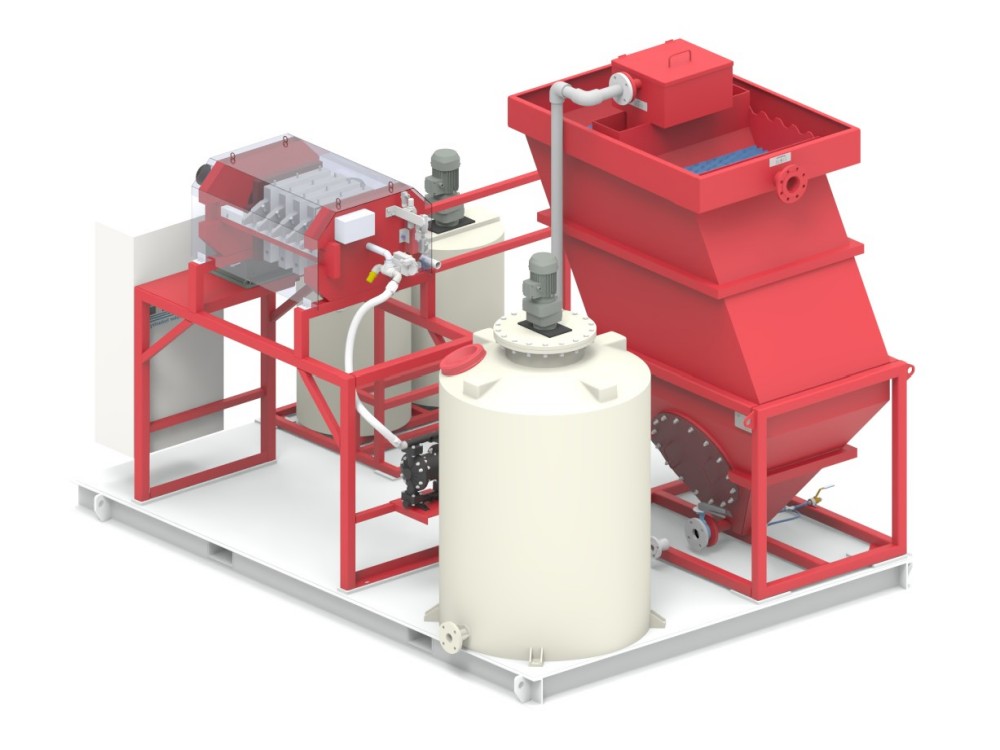

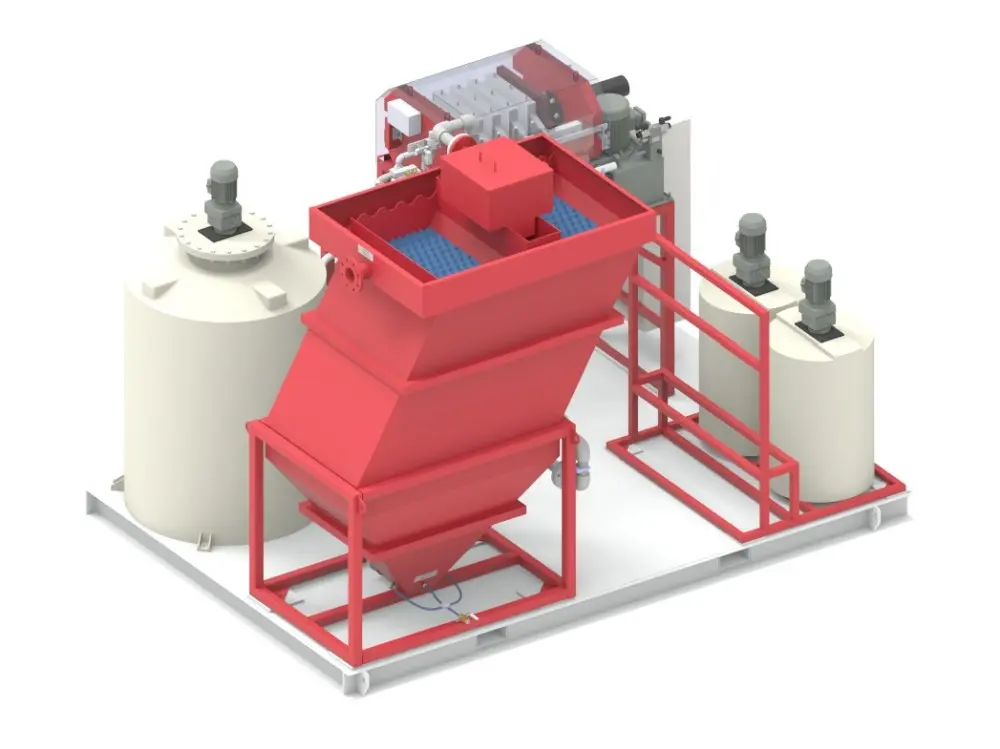

Biodegradation machine

equipment characteristics

1. AISI304 Stainless steel shell, no odor;

2. High temperature aerobic microbial degradation technology;

3. Intelligent control, automatic operation, easy installation and maintenance;

4. It is equipped with a time control switch, which can flexibly control the start and stop of the equipment according to the working time of the kitchen, so as to save more energy;

5. With the optional Internet of Things system, the system status can be viewed remotely, alarm can be automatically uploaded, built-in mini program, garbage room monitoring and other functions.

Applicable scenarios

Hotels, commercial complexes, residential areas, buildings, restaurants, hotels, canteens, food processing plants, food courts and other centralized garbage disposal houses.

Equipment model and parameters

Model |

Size (mm) |

Processing capacity (KG/D) |

Power (kw) |

Reference price (YUAN) |

KQ-KG-JJ-500 |

1800*1000*1300 |

500 |

10 |

120000 |

KQ-KG-JJ-1000 |

2500*1000*1300 |

1000 |

16 |

200000 |

KQ-KG-JJ-1500 |

2500*1100*1100 |

1500 |

20 |

300000 |

KQ-KG-JJ-2000 |

3200*1200*1600 |

2000 |

25 |

400000 |

Installation requirements

1. Before installation, the height of the existing drainage pipe must be confirmed;

2. The garbage room must reserve a ventilation pipe for the exhaust of the degradation machine, which needs to be discharged at high altitude and at least to the highest point of the building;

3. Power supply: AC 380V (3P+N+PE).

4. Ensure that there is sufficient oil in the heat transfer oil tank before installation and commissioning.

Equipment principle

Based on the distinct characteristics of kitchen waste, which typically includes a high content of organic matter, moisture, and a complex mixture of food residues, a meticulous process of screening and production of high - temperature aerobic microbial agents has been carried out. These microbial agents are specifically formulated to thrive in elevated temperature environments. They are carefully selected from a vast array of microorganisms due to their unique ability to rapidly break down various components found in kitchen waste.

Once the microbial agents are produced, they are introduced into specialized treatment equipment. Inside this equipment, under precisely controlled high - temperature conditions, the agents initiate an accelerated decomposition process. The high - temperature environment provides an optimal setting for the microorganisms to be highly active, enabling them to quickly consume and break down the organic substances within the kitchen waste. This rapid decomposition not only significantly reduces the volume of the waste but also stabilizes its composition, making it more manageable and less prone to producing unpleasant odors or attracting pests during the treatment process.

Through this high - temperature aerobic decomposition, kitchen waste can be effectively treated, achieving a remarkable degree of degradation. The output, or the degraded residue, has significant potential for further utilization. It can be subjected to additional processing steps to transform it into high - quality organic fertilizer. This organic fertilizer is rich in nutrients that are beneficial for plant growth, such as nitrogen, phosphorus, and potassium. Alternatively, it can be directly mixed with soil at appropriate ratios. When incorporated into the soil, it helps to improve soil structure, enhance soil fertility, increase water - holding capacity, and promote the healthy growth of plants, thereby playing a crucial role in sustainable agriculture and environmental protection.