Industrial recycling is an essential component for sustainable business practices. According to the Environmental Protection Agency, recycling metals can save 95% of the energy needed to produce new aluminum. This significant energy reduction highlights the importance of integrating industrial recycling into operations.

Michael Green, an expert in waste management, states, “Businesses that adopt industrial recycling can reduce costs and improve their sustainability profile.” His insights emphasize the necessity for companies to rethink their waste strategies. Many industries still overlook the potential benefits of recycling. This oversight can lead to missed opportunities for reducing waste and saving money.

Implementing industrial recycling is not without its challenges. Companies must invest in infrastructure and training. A lack of knowledge can hinder progress in this area. However, the long-term benefits far outweigh the initial hurdles. More businesses need to reflect on their recycling practices and take actionable steps forward.

Industrial recycling plays a crucial role in sustainability for businesses. It helps minimize waste and reduces environmental impact. By recycling materials, companies can lower costs and create new revenue streams. This shift not only aids in conservation but also enhances brand reputation.

Implementing an industrial recycling program can seem daunting. Start by assessing the waste your business produces. Identify recyclable materials like metals, plastics, and paper. Create a clear plan for collection and sorting. Engage employees throughout the process. Their involvement can improve compliance and efficiency.

Tips: Consider partnering with a local recycler. They can provide guidance and resources. Regularly track your recycling efforts. Analyze what works and what doesn’t. Adjust your strategies as needed. Embrace a mindset of continuous improvement. Small changes can lead to significant impacts.

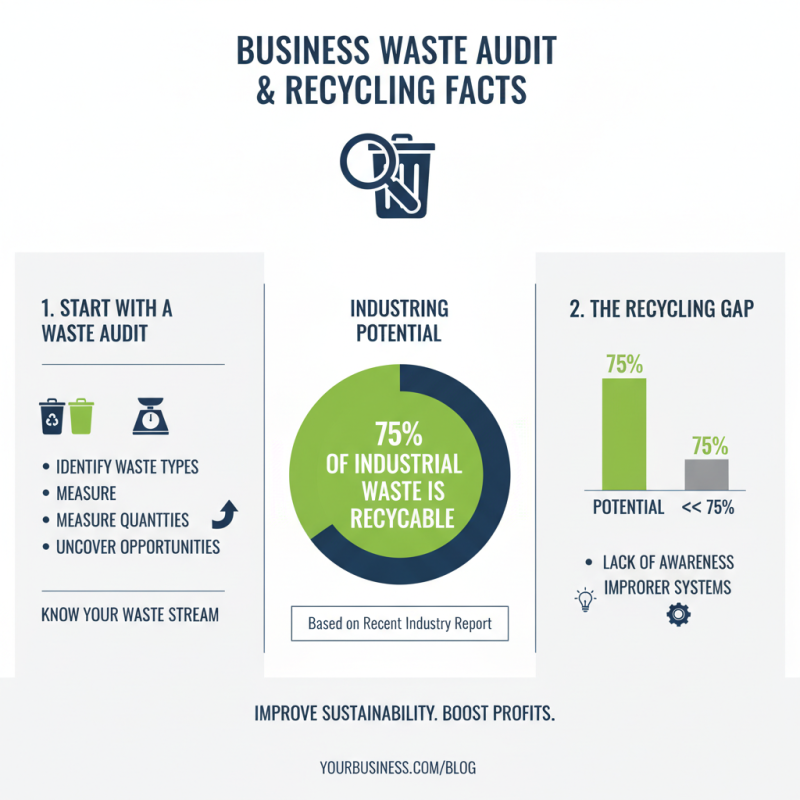

To assess your business's current waste management practices, begin by conducting a thorough waste audit. This audit will help identify the types and quantities of waste your business generates. According to a recent industry report, around 75% of all waste in the industrial sector can be recycled. However, many businesses only recycle a fraction of this, often due to lack of awareness or proper systems.

Take a close look at your waste disposal methods. Are you using single-stream recycling? If so, it might lead to contamination. Keeping recyclables separate can improve the quality of material collected. Remember, about 30% of recyclables end up in landfills due to contamination issues. This statistic highlights the need for better sorting practices.

Tip: Create a team dedicated to waste management. Regular training sessions can keep everyone informed about best practices. Implement clear signs for recycling bins to reduce errors. Track your progress quarterly. Set measurable goals, such as increasing recycling rates by 20% within a year. This practice not only helps the environment but can also reduce disposal costs, as less waste will need to be transported to landfills.

Identifying materials for recycling can seem difficult. Begin by evaluating the waste your business produces daily. Common industrial materials to look at include metals, plastics, and cardboard. Each type has its own recycling process, making it essential to understand them. For example, stainless steel can frequently be recycled, but contaminated metals might not be.

Consider conducting a waste audit. This helps in pinpointing what materials are recyclable. Examine your production process. Are there leftover materials that could be reused? For instance, scrap metal from manufacturing can often be melted down and remade into new products. However, separating recyclable waste from non-recyclable can be challenging.

Make a list of potential recyclable materials. It can be easy to overlook some items. Jot down what comes in and what goes out. Engage with your team. Encourage them to share ideas on recyclables. This approach could elicit unexpected solutions. With time, you will discover patterns and improve your recycling efforts.

To start industrial recycling effectively, a solid recycling plan is crucial. Assess your current waste management practices. Identify materials that can be recycled, like metals, paper, and plastics. Involve your employees by educating them about recycling. Clear communication will ensure everyone understands the importance of this initiative.

Tips: Create visual aids to remind staff of recycling stations. Use simple signs to differentiate waste types.

Develop a strategy that outlines goals and timelines. Consider collaborating with local recycling facilities. They can offer insights and resources. Regularly track your recycling progress. Adjust your plan based on what works and what doesn’t. Failure may happen, but adapt quickly.

Tips: Hold monthly meetings to discuss challenges and successes. Encourage suggestions from team members to enhance the strategy.

Establishing partnerships with recycling companies is crucial for businesses aiming to start industrial recycling. The recycling sector has seen growth, with a report from the World Economic Forum stating that improving recycling processes could save over $200 billion annually. Forming connections with local waste management firms can facilitate knowledge sharing and resource optimization.

Collaboration brings benefits but also challenges. Not all recycling companies handle the same materials. This disparity can complicate your recycling strategy. Research shows that companies that evaluate their partners' capabilities often enjoy a 30% improvement in recycling efficiency. Understanding what each partner offers is key.

Engaging with industry organizations can further enhance your efforts. These groups often provide valuable insights and access to best practices. However, navigating these relationships can be tricky. Transparency and clear communication are essential. A 2021 study indicated that businesses with clear expectations saw a 25% increase in partnership satisfaction. Being open about your goals can lead to more productive collaborations.

| Recycling Material Type | Collection Frequency | Partnership Type | Potential Revenue ($) | Environmental Impact (CO2 Reduction) |

|---|---|---|---|---|

| Plastic | Weekly | Local Recycling Company | 500 | 200 kg |

| Paper | Bi-weekly | National Organization | 300 | 150 kg |

| Metals | Monthly | Local Scrap Yard | 700 | 300 kg |

| Electronics | As needed | Specialized E-Waste Company | 1000 | 400 kg |

| Glass | Monthly | Local Glass Recycler | 200 | 100 kg |