In today's rapidly evolving industrial landscape, optimizing your Industrial Water Treatment Plant (WTP) is essential for enhancing efficiency and ensuring peak performance. As industries face increasing pressure to minimize water consumption and adhere to stringent environmental regulations, a well-optimized WTP not only boosts operational productivity but also contributes to sustainable practices. This ultimate guide will explore the key strategies and best practices for maximizing the effectiveness of your Industrial WTP. From advanced filtration techniques to the integration of smart technology and data analytics, we will delve into the innovative solutions that can transform your water treatment processes. Join us as we uncover the essential components that lead to a seamless, high-performing Industrial WTP, empowering you to meet both operational goals and environmental responsibilities.

Understanding the key components of Industrial Water Treatment Plants (WTPs) is critical for enhancing their efficiency and performance. At the heart of any WTP is the filtration system, which is essential for removing suspended solids, bacteria, and other contaminants from water. Various filtration methods, such as sand, membrane, and carbon filters, can be employed depending on the specific needs and challenges faced by the facility. Choosing the right filtration technology not only improves water quality but also prolongs the lifespan of downstream equipment.

Understanding the key components of Industrial Water Treatment Plants (WTPs) is critical for enhancing their efficiency and performance. At the heart of any WTP is the filtration system, which is essential for removing suspended solids, bacteria, and other contaminants from water. Various filtration methods, such as sand, membrane, and carbon filters, can be employed depending on the specific needs and challenges faced by the facility. Choosing the right filtration technology not only improves water quality but also prolongs the lifespan of downstream equipment.

Another crucial aspect of WTPs is the chemical treatment process, which helps to balance water chemistry and eliminate harmful substances. This involves the use of coagulants and flocculants to facilitate the aggregation of contaminants, aiding in their removal. Moreover, incorporating advanced sensors and Control Systems for monitoring water quality in real-time significantly boosts operational efficiency. By ensuring that all components work synergistically, plants can achieve optimal treatment performance, reduce operational costs, and meet regulatory compliance with ease. Understanding each component's role fosters an integrated approach that maximizes the overall effectiveness of the water treatment process.

Assessing the performance metrics of your water treatment processes is crucial for optimizing efficiency. Recent analyses of wastewater treatment plants reveal that the average energy efficiency is only 0.287. This highlights the need for facilities to evaluate their operational age and technology, as these factors significantly influence overall performance. By implementing a comprehensive assessment system that includes key performance indicators (KPIs), plants can identify areas for improvement and adopt modern treatment techniques, such as A2/O-MBR or FMBR, which have shown enhanced effectiveness in various studies.

Assessing the performance metrics of your water treatment processes is crucial for optimizing efficiency. Recent analyses of wastewater treatment plants reveal that the average energy efficiency is only 0.287. This highlights the need for facilities to evaluate their operational age and technology, as these factors significantly influence overall performance. By implementing a comprehensive assessment system that includes key performance indicators (KPIs), plants can identify areas for improvement and adopt modern treatment techniques, such as A2/O-MBR or FMBR, which have shown enhanced effectiveness in various studies.

Tips for Optimization:

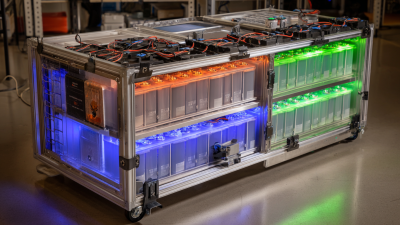

Implementing advanced technologies in industrial water treatment plants (WTPs) is crucial for optimizing efficiency and performance. One effective approach is integrating automated monitoring systems that utilize IoT (Internet of Things) sensors. These sensors provide real-time data on water quality, flow rates, and chemical dosing, enabling operators to make informed decisions instantly. By leveraging this data through machine learning algorithms, WTPs can predict potential issues and streamline operations, reducing downtime and maintenance costs.

Another promising technology is membrane filtration, which enhances the removal of contaminants and improves overall process efficiency. The adoption of advanced membranes, such as hollow fiber and ceramic types, allows for better tolerance to fouling and longer operational lifespans. Coupled with automated backwashing systems, these membranes can maintain their performance with minimal human intervention. Furthermore, incorporating energy recovery devices can significantly reduce energy consumption, making the water treatment process not only more efficient but also more environmentally sustainable.

Embracing these advanced technologies positions industrial WTPs to meet growing regulatory demands and achieve optimal operational performance.

Regular maintenance is crucial for optimizing water treatment plants (WTPs) to ensure maximum efficiency and performance. According to a report by the American Water Works Association (AWWA), up to 20% of operational costs in Industrial WTPs can be attributed to equipment failure, which can largely be mitigated through regular maintenance strategies. Implementing a preventive maintenance schedule not only reduces the risk of unexpected breakdowns but also extends the lifespan of expensive equipment, translating to significant cost savings for organizations.

Moreover, analytics from a recent study conducted by the Environmental Protection Agency (EPA) highlight that facilities actively engaging in routine maintenance practices improve their operational performance rates by approximately 15%. These practices include regular inspections, timely replacements of worn components, and employee training programs that ensure staff are equipped with the latest knowledge on system operations. Emphasizing a culture of maintenance not only promotes safety but also enhances compliance with environmental regulations, thereby boosting overall plant performance and sustainability.

Training your workforce is a crucial step in optimizing your industrial Water Treatment Plant (WTP) for maximum efficiency and performance. A well-trained team not only enhances the operational effectiveness of water treatment processes but also ensures compliance with environmental regulations. Implementing a comprehensive training program that covers the technical aspects of water treatment, safety protocols, and troubleshooting methods can empower employees to handle various challenges that arise in the day-to-day operations of a WTP.

Moreover, fostering a culture of continuous learning encourages employees to stay updated with the latest technologies and industry best practices. Regular workshops, hands-on training sessions, and certifications can significantly boost the skill sets of your workforce, leading to increased productivity and lower operational costs. By investing in employee development, you create a knowledgeable team that can identify inefficiencies and suggest improvements, ultimately driving the overall performance of the WTP.